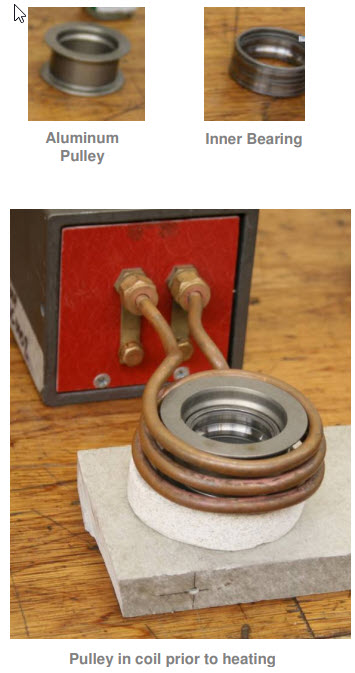

Note: Shrink fitting aluminum pulley to insert inner bearing

Objective:

Heat aluminum pulley for insertion of an inner bearing for the automotive industry

End Product:

pulley

Equipment:

Ambrell 2 kW induction heating system, equipped with a remote workhead containing two 0.33μF capacitors for a total of 0.66μF An induction heating coil designed and developed specifically for this application.

Materials:

Aluminum pulley 2.3 in (60 mm) OD x 1.6 in in (40 mm) ID x 1 in (27 mm) high and inner bearing 0.7 in (17.8 mm) high x 1.6 in (40 mm) dia

Temperature:

464 °F (240 °C)

Frequency:

283 kHz

Testing:

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 °F (240 °C) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

Benefits:

-

Defined and controlled heat pattern

-

Process easily integrated into automated system

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000