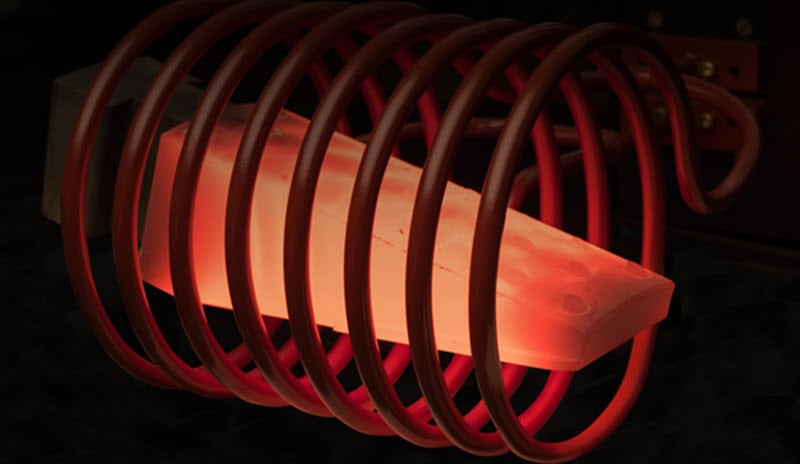

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

In the ever-changing world of manufacturing, efficiency, precision, and sustainability are critical. So, it's no surprise that induction heating continues to gain in popularity throughout industry.

But what exactly makes it so advantageous? Let's look at the top 10 reasons why induction heating could benefit your manufacturing process:

Induction heating utilizes electricity instead of fossil fuels, boasting energy efficiency of up to 90%. This translates to lower energy bills and a reduced carbon footprint, helping your organization meet carbon neutrality targets.

Induction heating heats materials directly and rapidly, reducing processing times compared to traditional methods. This means faster production cycles and increased output.

Unlike flame heating, induction allows for precise heating of specific areas. This minimizes unwanted heat zones, reduces distortion, and ensures consistent product quality.

Open flames and fumes? Not with induction. Induction heating is a flameless process, creating a safer working environment for your team. No more burns or harmful airborne particles.

From metals to semiconductors, induction heating caters to a diverse range of materials. Its versatility makes it a valuable tool for various applications, reducing the need for multiple heating systems.

Precise heating means predictable results. Induction heating minimizes the risk of overheating and uneven heating, leading to fewer defects and consistent product quality.

Unlike furnaces with their wear and tear, induction heating systems have minimal moving parts. This translates to longer equipment life, reduced maintenance costs, and less downtime.

No need for guesswork. Induction heating offers precise temperature control and repeatability, ensuring consistent results batch after batch. This improves quality control and reduces manufacturing variability.

It's not just about energy efficiency. Induction heating minimizes material waste thanks to its targeted heating approach. This conserves resources which translates to cost savings.

No combustion byproducts mean a cleaner workplace and environment. Induction heating reduces airborne contaminants, thus improving air quality and worker well-being.

Induction heating is green, efficient, and precise. With its extensive list of benefits, induction heating is more than just a heating method; it's a strategic investment that will help your bottom line while offering environmental benefits. Learn more about induction heating on our website.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...