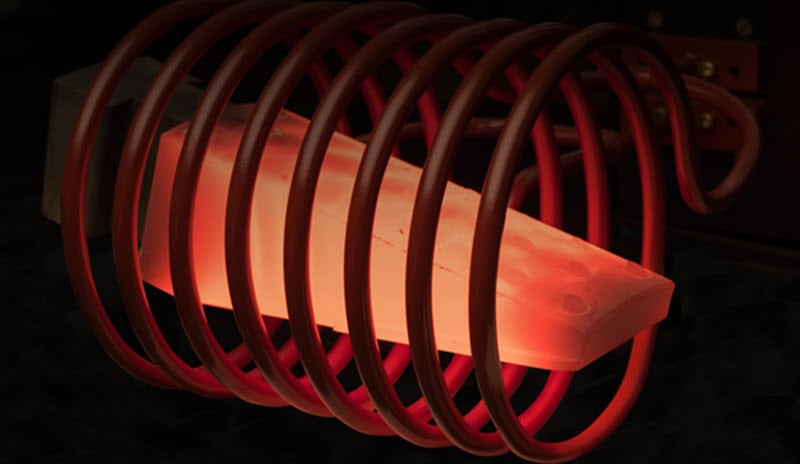

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

Induction heating is a highly efficient and versatile technology with numerous industrial applications. Unlike traditional heating methods that rely on heat transfer through conduction or convection, induction heating directly heats the workpiece itself through electromagnetic induction. This unique principle offers several advantages that contribute to its superior efficiency:

Induction heating eliminates the need for intermediate heat transfer mediums like flames or heating elements. This direct energy transfer to the workpiece minimizes heat loss to the surrounding environment, significantly improving energy efficiency.

The electromagnetic field can be precisely controlled to heat specific areas of the workpiece, reducing the amount of energy wasted on heating unnecessary portions of the part.

Induction heating can achieve extremely rapid heating rates. This translates to shorter processing times, increased production throughput, and reduced energy consumption.

The localized and rapid heating minimizes the time the workpiece is exposed to elevated temperatures, reducing the risk of oxidation, distortion, and material degradation.

The power output of the induction heating system can be precisely controlled, allowing for accurate and repeatable temperature profiles. This ensures consistent and high-quality results in various applications.

Induction heating is a non-contact process, eliminating the risk of contamination from contact with heating elements or flames.

Induction heating is an environmentally friendly technology with minimal emissions. It eliminates the need for fossil fuels and significantly reduces greenhouse gas emissions compared to traditional heating methods.

The non-contact nature of induction heating minimizes the risk of contamination and ensures a cleaner working environment.

The efficiency and versatility of induction heating make it suitable for a wide range of applications, including:

Heat Treating: Hardening, annealing, tempering, brazing, and soldering of metals.

Forging and Forming: Heating of metal billets for forging and forming processes.

Melting and Casting: Melting of metals for casting and other applications.

Surface Engineering: Induction hardening of surfaces for improved wear resistance.

Brazing and Soldering: Joining of metal components using induction heating.

Induction heating is a highly efficient and sustainable technology with numerous advantages over traditional heating methods. Its direct energy transfer, rapid heating capabilities, precise control, and environmental benefits make it an increasingly popular choice in various industrial sectors. You can learn more about induction heating on our website.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...