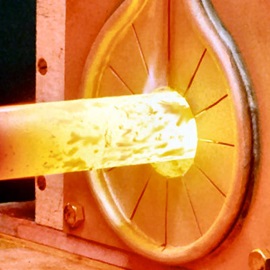

Hot Forming

Discover the advantages of induction heating!

- Home

- How It's Used

- Hot Forming

Induction Benefits

-

Meets tight production tolerances with precise localized heat to small areas creating pinpoint accuracy

-

Increases production rates with faster heating cycles

-

Reduces defect rates with repeatable, reliable heat

-

Eliminates variability from operator-to-operator, shift-to-shift

-

Maintains metallurgical characteristics of the individual metals

Video

Benefits

Here are the advantages of hot forming with induction heating:

- springback effect is eliminated

- ductility is improved

- low pressure & minimal residual part stress

- better grain flow & microstructure

- improved mechanical properties

- reduced need for post production tempering & heat treating

- improved production rates with minimal defects

Expertise

Induction heating in hot forming is applied for several different purposes:

Heading - forming a head on blot, screw or rivet

Blanking - cutting a whole piece from sheet metal

Punching - cutting a hole

Slotting - cutting of elongated holes

Perforating - cutting a group of holes

Trimming - cutting away excess metal

Shearing - cutting in straight line across piece

Bending - producing single, double, straight flange, edge hem, curl or double hem bends

In order for the hot forming process to succeed, an application should be tested including the following variables. Ambrell's experienced applications engineers will provide you with the necessary advice and recommendation.

|

Variable |

Cold Form |

Warm Form |

Hot Form |

|

Temperature |

ambient |

400-900° F 205 - 480°C |

1300-2000° F 705 - 1090°C |

|

Die Pressure |

high |

lower |

lowest |

|

Stress |

residual |

medium |

minimal |

|

Grain Flow |

good |

better |

best |

|

Scaling |

none |

less |

more |

-

How Can Hot Forming with Induction Improve Production Speeds?

Consistent uniform heating with induction helps reduce scrap and process variations.

-

Is there a variable that falls between Warm Form and Hot Form?

yes, however the temperature achieved should not change the material properties of the metal.

-

Are there any limitations with bending when using hot forming?

Usually bending with hot forming is optimal.

-

Your suggestion for a hot forming question and answer

Our Systems for hot forming with Induction

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

AMBRELL Ltd.

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service