Note: Shrinkfitting a steel mud pump liner

Objective:

Shrink fitting a steel liner into a cylinder to create a mud pump liner used in the oil industry

End Product:

mud pump

Equipment:

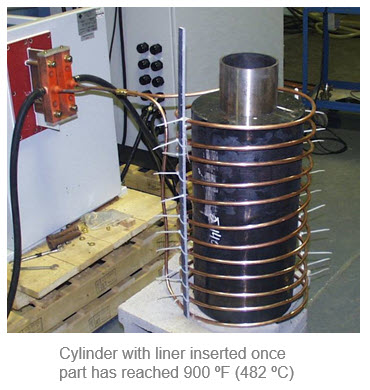

Ambrell 250 kW, 10 kHz induction heating system, equipped with a remote workhead containing one 53.6μF capacitor. An induction heating coil designed and developed specifically for this application.

Materials:

Steel cylinder 10.625 in (27 cm) OD with a 2.625 in (6.6 cm) thick wall and 21.75 in (55.2 cm) long, liner 5.5 in (14 cm) OD and 26.375 in (67c m) long

Temperature:

900 °F (482 °C)

Frequency:

7.8 kHz

Testing:

An eleven-turn helical coil is used to heat the cylinder. The cylinder is placed inside the coil and power is applied for 10 minutes to reach the temperature of 900 °F (482 °C). Once the temperature is reached the steel liner slides easily into the cylinder and the assembly is cooled to create the shrink fit

Benefits:

Induction heating provides:

-

Faster heat cycle

-

Increases production rate versus furnace systems

-

No preheat cycle or controlled cooldown required, reduces energy cost

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000