Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

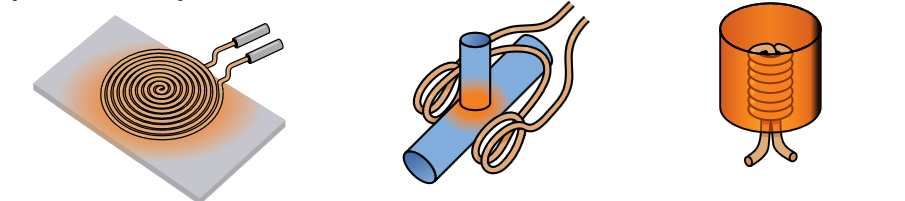

An induction heating system consists of a power supply, workhead and an induction coil (also known as inductor). The latter delivers the heat / current to the part. And although most of us think that induction coil 'wraps around' the piece, coil making in a true art!

From single - turn, to multi - turn, through multi position coils and pancake inductors. Sounds interesting, doesn't it? It gets even better - Ambrell can make all these induction coils for all your applications. Our guide introduces you to the art of coil fabrication.

A proper coil design is essential to achieving the effectiveness and efficiency parameters in your heating process. Let us guide you.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...