Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

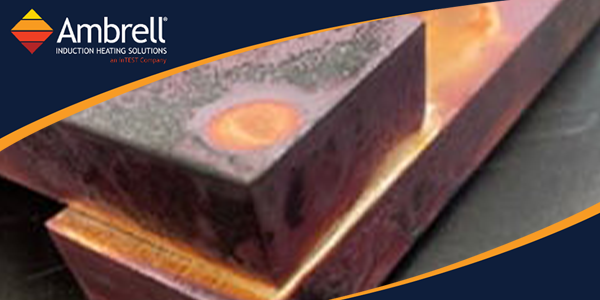

A company wanted to braze copper buss plates without using torches. They turned to THE LAB at Ambrell to validate the viability of their heating application when using induction. They were considering switching from torches to induction because of its repeatability, speed, and enhanced safety thanks to there being no open flame.

THE LAB determined that an Ambrell EKOHEAT 45 kW, 50-150 kHz induction heating power supply with a custom-designed induction heating coil would work well for this application. Initial tests were conducted to optimize the power delivered to the part and to understand the heating patterns achieved. The target temperature was 1400 °F (760 °C).

After several changes and iterations on the coil setup testing took place. Heat times of 3-5 minutes were achieved for the copper buss plates. Braze alloy was preplaced into the joint as the copper bars heated to temperature. A foot pedal operation would allow operator to have flexibility in pulsing the power into the joint as needed. The heat time met the client's objectives.

As mentioned, speed, repeatability, and safety were the primary reasons the client was assessing induction, and induction was beneficial on all fronts. With a torch, operator skill is crucial, making repeatability an issue at times. With induction they will see the same result each time. Induction also delivers less heat into the work environment and there is no open flame, offering a safety benefit. Finally, the expertise of THE LAB allowed the client to have peace-of-mind knowing their application would work prior to making an investment.

If you have a brazing application you'd like tested by THE LAB at Ambrell, contact us today to take advantage of free induction heating application testing. We'll send your parts back for inspection, along with providing a video showing you the heating process. You can even visit us at one of our two applications labs to view the testing in-person.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...