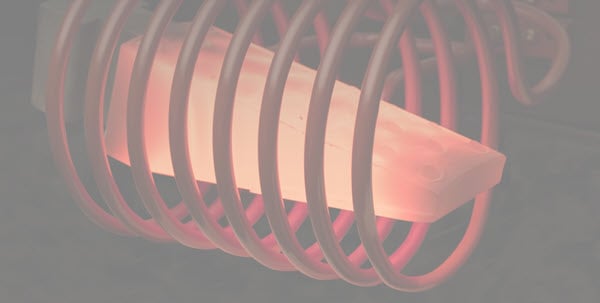

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

3 min read

Brett Daly

8/15/22 9:26 AM

Coupling is the transfer of energy that occurs in the space between the heating portion of the coil and the workpiece. So, coupling distance refers to the space needed to balance efficiency and manufacturing requirements.

Download our full induction coil design guide.

Generally, distance increases with the diameter of the part, typical values being 0.75, 1.25, and 1.75 inches (19, 32 and 44 mm) or billet-stock diameters of approximately 1.5, 4 and 6 inches (38, 102, and 152 mm), respectively.

When the length of the coil exceeds 4x to 8x its diameter, uniform heating at high power densities becomes difficult. In these instances, single-turn or multiple-turn coils that scan the length of the workpiece are often preferable.

In static surface heating, in which the part can be rotated but is not moved through the coil, a coupling distance of 0.060 inch (0.15 cm) from part to coil is recommended.

For progressive heating or scanning, a coupling distance of 0.075 inch (0.19 cm) is usually necessary to allow for variations in workpiece straightness.

A fine-pitch, multiple-turn coil closely coupled to the workpiece develops a very uniform heating pattern.

Similar uniformity can be achieved by opening up the coupling between the part and the coil so that the magnetic flux pattern intersecting the heated area is more uniform. However, this also decreases energy transfer.

Where low heating rates are required, as in through-heating for forging, this is acceptable. When high heating rates are needed, it’s best to maintain close coupling. The pitch of the coil should be opened to prevent overloading of the generator.

For through-heating of magnetic materials, multiple-turn inductors and slow power transfer are utilized. Coupling distances can be looser in these cases — on the order of 0.25 to 0.38 inch (0.64 to 0.95 cm).

It is important to remember, however, that process conditions and handling dictate coupling. If parts are not straight, coupling must decrease.

At high frequencies, coil currents are lower and coupling must be increased. With low and medium frequencies, coil currents are considerably higher and decreased coupling can provide mechanical handling advantages.

In general, where automated systems are used, coil coupling should be looser. The coupling distances given above are primarily for heat treating applications in which close coupling is required.

In most cases, the distance increases with the diameter of the part, typical values being 0.75, 1.25, and 1.75 inches (19, 32 and 44 mm) or billet-stock diameters of approximately 1.5, 4 and 6 inches (38, 102, and 152 mm), respectively.

Efficiency of coupling between the windings is inversely proportional to the square of distance between them.

Coil efficiency is the energy delivered to the coil that is transferred to the workpiece. This is NOT the same as overall system efficiency.

Typically, helical coils used to heat round workpieces have the highest values of coil efficiency. Internal coils have the lowest values.

It is important to note that, with the exception of the pancake and internal coils, the heated part is always in the center of the flux field. Regardless of the part contour, the most efficient coils are essentially modifications of the standard, round coil.

A conveyor or channel coil, for example, can be looked at as a rectangular coil whose ends are bent to form “bridges” in order to permit parts to pass through on a continuous basis. The parts, however, always remain “inside” the channels where the flux is concentrated.

Areas to be hardened are beside the center of the coil turns, and thus are kept in the area of heaviest flux.

When a wide heating zone is to be produced on the part, coupling over a greater area can be accomplished through the addition of a liner to the coil turn, or more ampere turns can also be produced with a multiple-turn channel inductor.

Channel-coil liners may also be configured to produce specialized heating patterns where greater heat densities are required in specific areas.

Need more info on coupling distance or coupling efficiency for your induction coil? Download our full induction coil design guide.

Want to get another set of eyes on your coil design? Our experts are always happy to chat. Contact us for personalized design assistance!

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...