Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Justyna Bakker

11/2/15 4:20 AM

When induction is properly implemented into a process, you can count on the same result every time. Operator inconsistency with a torch sometimes leads to varying results and uneven heating. And, if an operator leaves your organization, or you need multiple operators over different shifts or days, quality can become an issue.

Induction typically heats parts to temperature more rapidly than a torch, resulting in a higher production rate.

There is no open flame with induction, resulting in enhanced workplace safety. Additionally, it introduces less heat into the working environment, creating a better environment for employees.

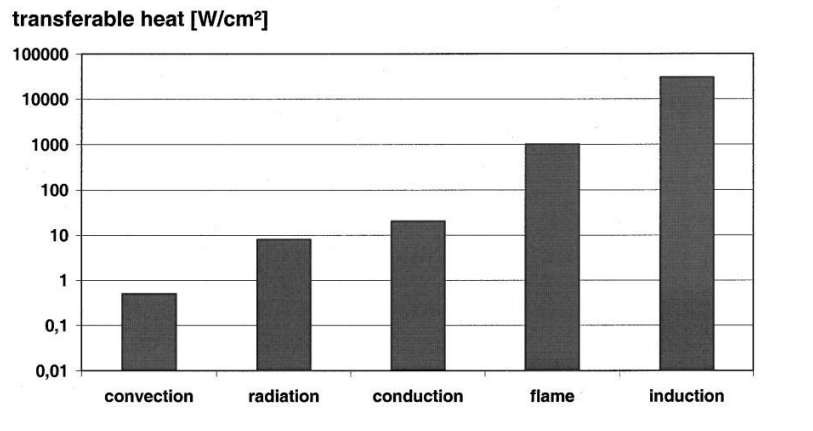

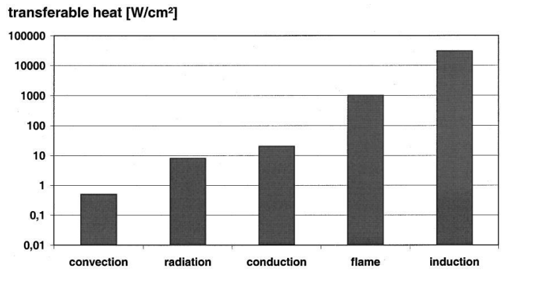

The above graphic compares induction heating with other heat sources. More transferable heat means that the energy is used and transferred in a localized, precise manner. The graphic illustrates that induction heating outperforms other heating methods like convection, radiation, conduction and flame when it comes to transferable heat.

So, in summary, the benefits of induction are a production-boosting rate of heating, less environmental footprint due to reduced energy use, and enhanced workplace safety. In short, induction helps you become cleaner and greener.

Expert guidance is critical when determining the right induction solution for an application. Are you considering switching from torch or furnace heating to induction? Learn more about our highly regarded lab testing service from THE LAB at Ambrell. Are you interested in learning more about the benefits of induction heating? Take a look at our extensive video library and see induction heating in action.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...