1 min read

Live from THE LAB: Tensile Test of Stainless Steel

Manufacturers in the aerospace industry face two primary challenges: advancing materials...

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Manufacturers in the aerospace industry face two primary challenges: advancing materials...

1 min read

Induction heating can effectively deliver localized heat to parts of virtually all shapes and...

1 min read

Induction heating can be applied to a huge variety of processes. At our best-in-class applications...

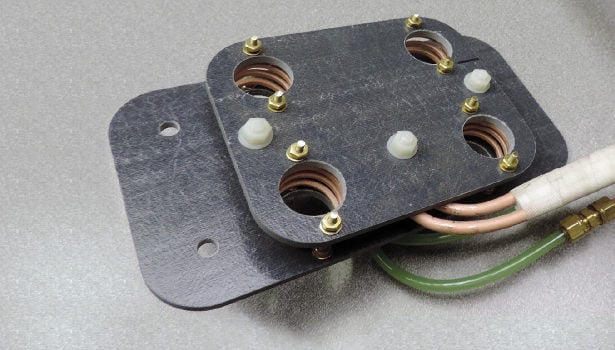

Induction heating can be applied to all sorts of applications. One of them is material testing. The...

1 min read

Ambrell, a leading manufacturer of induction heating systems, has sold an EASYHEAT 2 kW/150-400 kHz...

1 min read

Ambrell, a leading manufacturer of induction heating systems, has sold an EKOHEAT 15 kW/100 kHz...

1 min read

Ambrell, a leading manufacturer of induction heating systems, has sold an EASYHEAT 2 kW/150-400 kHz...

2 min read

Flexible tubes and hoses are increasingly an essential subset of a number of tube and pipe...

1 min read

Brazing is perhaps our most popular induction heating application. We consistently see companies...

Induction heating can be applied in a wide variety of industries. Some time ago, we completed an...

1 min read

Metal to plastic insertion (also called heat staking or indirect induction heating) is a popular...

1 min read

Brazing is a way of joining two metals. Usually, brazing requires the use a a filler material, for...

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service