Note: Heating Busbars for Coating Release

Objective:

To heat tin-coated copper bus bars for a coating release application for an engineering firm

End Product:

Bus bars

Equipment:

Ambrell EKOHEAT 50 kW, 15-45 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Tin-coated copper bus bar

Temperature:

177 °C (350 °F)

Frequency:

33 kHz

Testing:

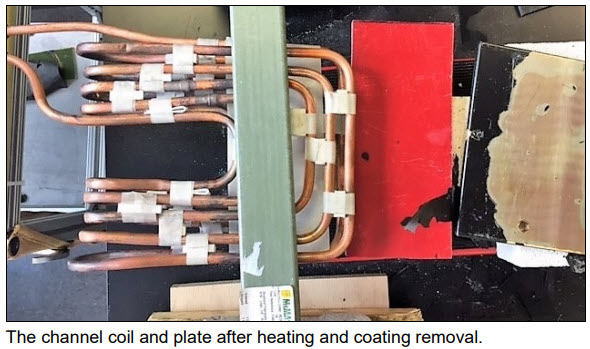

THE LAB designed a single position multiple-turn channel coil for this application. A 7.5 x 4.5 in (191 x 114 mm) area of the busbar required heating. After applying temperature indicating paint to the part, it took 35 seconds to heat the sample to temperature. The coating was then removed from the tin-coated copper plate. Heating longer length bars would increase the heating time by 10-15 seconds due to conduction losses.

Benefits:

-

Speed: The part heated to temperature in just 35 seconds, meeting the client's objectives

-

Precision: Induction's precision heating enable the part to heat to the exact targeted temperature, which prevented melting of the tin-coated copper part

-

Repeatability: Induction delivers the same result time after time, making it ideal for high-volume manufacturing process

-

Footprint: The space-efficient EKOHEAT worked perfectly in their workflow

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000