Note: Brazing Steel Hydraulics Fittings & Tubes

Objective:

To braze steel fittings and tubes to make hydraulic fittings within a targeted heating time of under 150 seconds.

End Product:

Hydraulic fittings

Equipment:

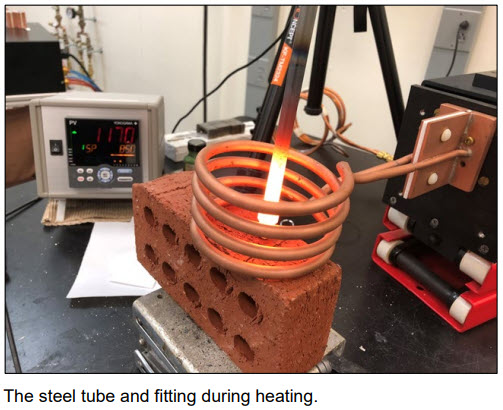

Ambrell EKOHEAT 15 kW, 50-150 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Steel tubes and fittings

Temperature:

2012 °F (1100 °C)

Frequency:

76 kHz

Testing:

A custom-designed single position multiple-turn helical coil was built to generate the required heating for this brazing application. Initial tests were conducted to optimize the power delivered to the part. Initial tests were also conducted to determine the rate of heating and the heating pattern achieved. Once a satisfactory heating pattern was achieved, parts were heated to the target temperature within 120 seconds.

Benefits:

-

Speed: Induction exceeded the client"s time requirements and is often faster than other heating methods.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating.

-

Lab Expertise: The client came to THE LAB at Ambrell with specific heating requirements, and THE LAB was able to meet and exceed those requirements through the process they designed.

-

Atmospheric Heating: This client required heating in an atmosphere, and induction works well for atmospheric brazing.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000