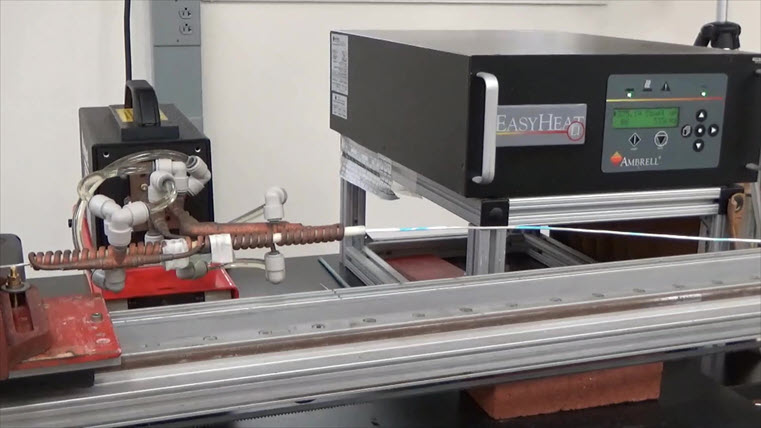

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

10/20/23 3:29 PM

Induction heating is a versatile and efficient method for wire and cable heating applications. It offers a plethora of advantages over conventional heating methods, making it a popular choice for various industrial applications.

Induction heating generates heat directly within the wire or cable, ensuring precise and localized heating. This eliminates the need for heating the entire workpiece, minimizing energy consumption and reducing the risk of damage to adjacent components.

Induction heating provides rapid heating and cooling rates, enabling quick and efficient processing of wire and cable products. This is particularly beneficial for applications where time is of the essence, such as with continuous production.

Induction heating is a highly repeatable and consistent process, ensuring that wire and cable products are heated to the desired temperature with minimal variation. This is critical for achieving high-quality results without variability.

Induction heating is a clean and environmentally friendly process that does not produce any emissions or combustion byproducts. This makes it an ideal choice for industries that are concerned about their environmental impact.

Induction heating is a safe and versatile process that can be used to heat a wide range of wire and cable products. It is also a non-contact method of heating, making it a safer heating method.

In addition to these benefits, induction heating also offers a number of other advantages for wire and cable heating applications. For example, induction heating can be used to heat wires and cables of various shapes and sizes, and it can be easily integrated into automated production lines.

Induction is a method worth serious consideration for wire and cable heating applications. It offers a range of benefits that make it a preferred choice for various industrial applications. Induction is a reliable, efficient, and environmentally friendly heating method. Our heating applications page covers several wire heating applications tested by THE LAB at Ambrell.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...