Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

In this blog post we'll provide a quick overview of the basics of induction heating. When current is passed through an inductor, a magnetic field is created around that wire. With an AC circuit the magnetic field will collapse and change polarity, as the current changes polarity. When a second conductor is placed in the alternating magnetic field, an alternating current will be generated in the second conductor. The current in this second conductor is proportional to the current in the first conductor and the inverse of the square of the distance between the two conductors.

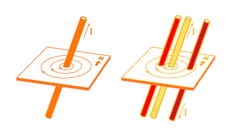

Induction heating makes use of this by replacing the wires with a coil and a work piece. The alternating current in the coil creates a magnetic field whose polarity changes at the frequency of the power supply. An alternating current is induced in the work piece by this magnetic field.

Induction heating makes use of this by replacing the wires with a coil and a work piece. The alternating current in the coil creates a magnetic field whose polarity changes at the frequency of the power supply. An alternating current is induced in the work piece by this magnetic field.

There are two methods of heating when using induction heating:

Eddy current heating from the losses in the work piece

Hysteretic heating in which energy is generated within the part by the alternating magnetic field changing the magnetic polarity of the work piece. Hysteretic heating occurs in the part up to the Curie temperature (typically near 770 °C/1400 °F) at which point hysteretic heating is minimized. As a note, hysteretic heating only occurs in magnetic steels. Non-magnetic materials such as copper and aluminum do not experience hysteretic heating.

The operating frequency of an induction heating system is very important as it has a direct effect on the penetrating ability of the heating effect. To understand this we need to first understand a phenomenon known as the “skin effect.” When the magnetic field induces a current in the part, it flows primarily at the surface of the part. A higher operating frequency will result in a shallower skin depth. A lower operating frequency will deepen the skin depth and the penetration of the heating effect.

To learn more, visit our "What Is Induction Heating" section on our website.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...