Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

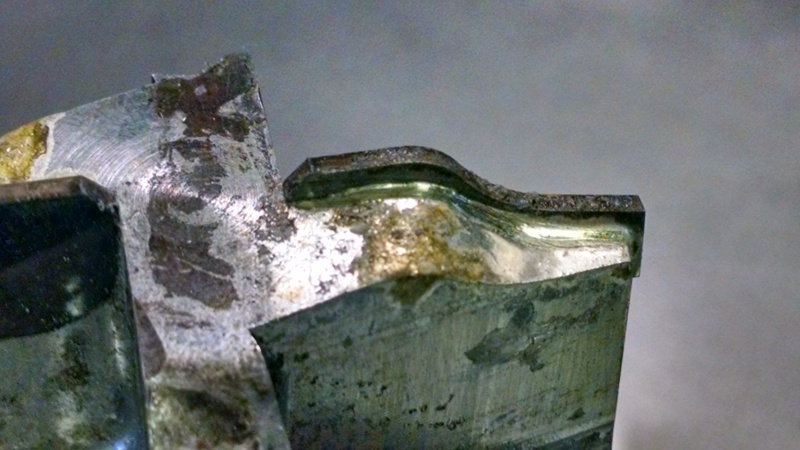

A client had been using an inexpensive imported induction heating system, but ran into quality issues that resulted in production down time. Consequently, they turned to THE LAB at Ambrell to develop the right solution for their application and enable the installation of a reliable EASYHEATTM induction heating system. The application involved heating steel cutting bits with diamond-carbide inserts for brazing and de-brazing. Cutting tools were the end product.

Ambrell's applications engineers determined that a 4.2 kW EASYHEAT would meet the client's objective of heating the part to 1400 oF (760 oC) within 25 seconds. A specially designed single-turn hairpin coil was developed for this heating application. Along with reliability, the modest size of the EASYHEAT is a benefit as it makes it easy to integrate the system into manufacturing processes such as this one.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...