Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

4/28/17 3:59 PM

A client had been using torches for heating parts prior to bending in the automotive accessory industry. However, they wanted to improve upon the speed, repeatability and safety that torch heating offered. Consequently, they turned to THE LAB at Ambrell to help them design a process that met their specifications and budgetary requirements.

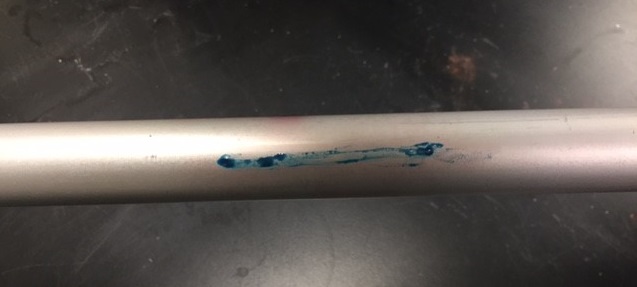

THE LAB determined that an Ambrell EASYHEATTM 3.5 kW induction heating system would achieve their heating time requirement of 120 seconds. For testing, a specially-designed single position multiple-turn split-helical coil was designed. Temperature indicating paint was applied to the part to identify when it achieved the targeted temperature of 500 oF (260 oC). Testing confirmed that the process was viable and the system could achieve the targeted heating time of two minutes.

The client benefited from speed gains and repeatability along with enhanced safety since induction doesn't introduce a flame into the work environment. Want to learn about other applications that THE LAB has assessed? Check out our applications library.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...