Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A company from the food industry came to THE LAB at Ambrell to see if induction might be a fit for their cap sealing (bonding) application. The application involved heating aluminum foil inside a plastic bottle. Induction's speed and repeatability were of particular interest to the client. Induction is an especially good fit for high volume production applications like this cap sealing application, which we'll discuss again later in this post.

More induction cap-sealing application notes

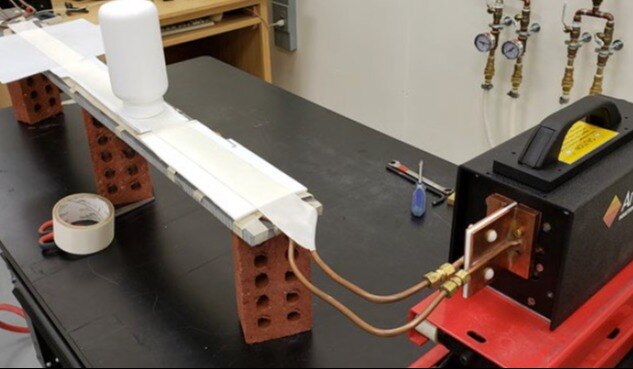

THE LAB determined that an Ambrell EASYHEATTM 4.2 kW, 150-400 kHz induction heating system would accomplish the client's objectives. A custom-designed single position multiple-turn pancake coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the assembly. Once a satisfactory heating pattern was achieved with the proper coil design, parts were traversed over the coil at a rate of about 45 bottles per minute. It was confirmed that the aluminum heated sufficiently to create a bond between the foil and the bottle, meeting the client’s goal.

As already mentioned, speed and repeatability are two considerable benefits of induction for cap sealing applications like this one. Repeatability means you'll get the same result every time, which prevents bottles from leaking and ensures freshness. Additionally, induction is ideal for high volume applications, which in this case involved 45 bottles being heated for cap sealing per minute. As we saw in this application, the coil design can work perfectly within the workflow of the manufacturing process.

If you have an application you'd like assessed, contact THE LAB to take advantage of complimentary induction heating application testing from our team of induction application experts.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...