Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

5/12/16 3:07 PM

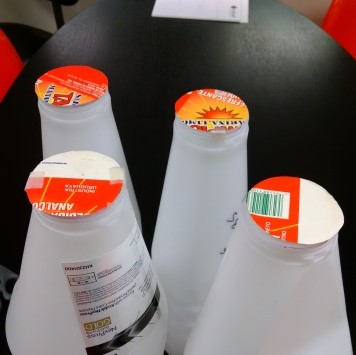

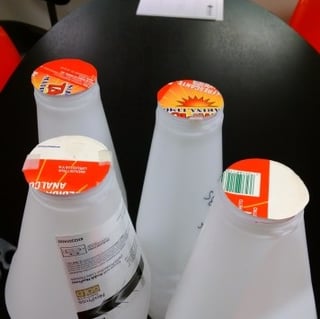

The objective of this application was to heat an aluminum seal for cap sealing to a plastic container. The client had been using another method for cap sealing which was more time and labor intensive. The client turned to THE LAB at Ambrell to see if induction heating with an Ambrell system could allow them to reduce their cap sealing process time to just seconds.

The engineers in THE LAB determined that an EASYHEATTM 1.2 kW induction heating system would be ideal for this application. A pancake style coil was designed specifically for this application. Testing determined that the cap sealing application could be completed in just over one second, exceeding the client's expectations.

Benefits of using induction for this application include speed, the minimal footprint required by an EASYHEAT induction heating system and the energy efficiency of induction heating. If you'd like to send your parts in for complimentary feasibility testing, visit THE LAB page and get the process started today.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...