Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

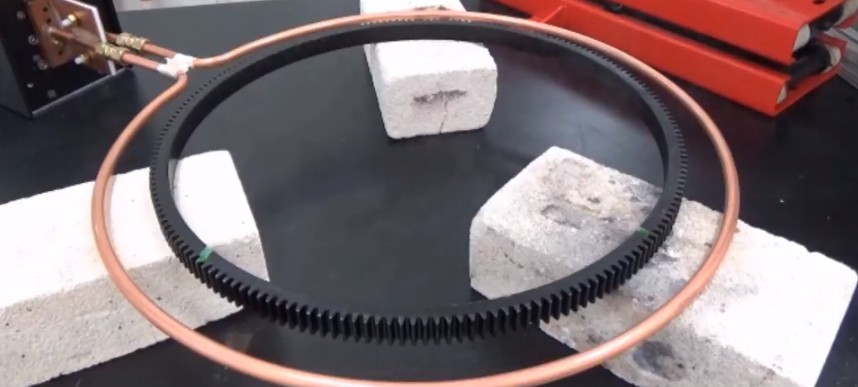

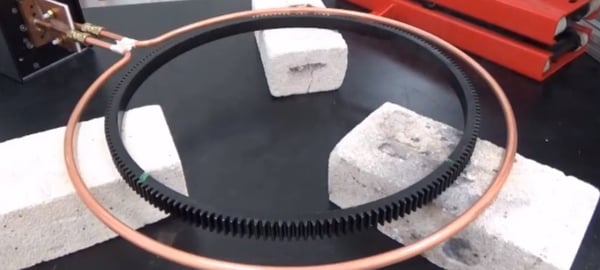

In the latest application video from THE LAB at Ambrell, a steel gear is heated to 400 °F (204 °C) for a shrink fitting application. An Ambrell EASYHEATTM 6 kW induction heating power supply is used. You'll see that temperature indicating paint -- which liquefies and turns clear when the target temperature is achieved -- is applied to two spots on the steel gear.

As you saw, the heat cycle was 40 seconds for this shrink fitting application with an EASYHEAT 6 kW induction heating power supply. To view other videos, check out our shrink fitting videos page. If you'd like to have the applications lab test your part(s), visit the lab service request page.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...