Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

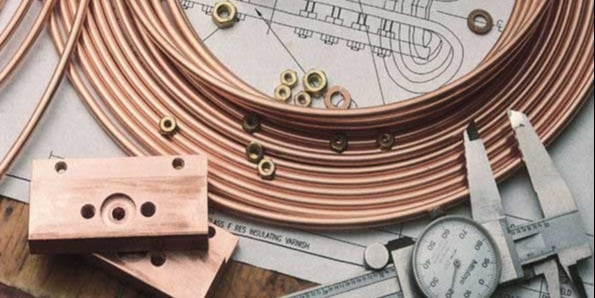

The coil is a critical component of any induction heating solution. Ambrell designs coils for its own systems and can also manufacture coils for other induction heating systems when a drawing is provided. We are dedicated to delivering high-quality coils with a focus on precision and reliability that meet the demands of our customers.

An induction coil, essentially a copper conductor shaped into a specific configuration, generates a magnetic field when an alternating current passes through it. This magnetic field penetrates the workpiece, inducing an electrical current within it. The resistance of the workpiece converts this induced current into heat, offering considerable control over the heating process.

Our state-of-the-art coil manufacturing facility has a fabrication shop that is equipped to handle a wide range of coil designs, from simple helical coils to complex multiple-turn configurations. Our skilled engineers from THE LAB at Ambrell work closely with customers to understand their specific heating requirements and design coils that deliver desired performance.

Coil Configuration: The shape and size of the coil are crucial factors in determining the heating pattern and efficiency.

Number of Turns: The number of turns in the coil influences the magnetic field strength and, consequently, the heating.

Cooling: Proper cooling is important to prevent overheating and maintain the coil's integrity.

Material Selection: The choice of copper tubing and insulation materials impacts the coil's durability and electrical performance.

Ambrell's commitment to excellence extends beyond coil manufacturing. Our team of experts offers a comprehensive process, including:

Coil Design: Our lab provides feasibility testing where we design a coil that meets your unique requirements.

Coil Fabrication: Utilizing state-of-the-art equipment and techniques to build coils from our testing.

Coil Testing and Validation: Rigorous testing to ensure optimal functionality as we test coils for our systems after they are manufactured to ensure quality.

Field Service and Support: Providing on-site assistance and troubleshooting if desired.

By partnering with Ambrell, you gain access to a wealth of expertise and cutting-edge technology to elevate your industrial heating processes. Have any questions about induction heating and induction heating coil design?

Read our comprehensive guide to designing induction coils or contact our experts for personal assistance.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...