Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

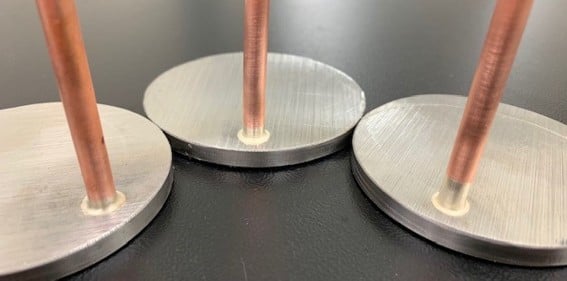

A company was looking to design a heating process for a new device they were developing, and they reached out to THE LAB at Ambrell to take advantage of their complimentary applications testing. The process involved brazing a copper tube and a steel plate. While this was a new process, the client also tested a torch as a part of their due diligence, and repeatability and quality were their top two priorities.

THE LAB at Ambrell determined that an Ambrell EASYHEATTM 6 kW, 150-400 kHz induction heating system was the right solution based on their application requirements. They also designed a single position multiple-turn helical coil for the testing. Temperature indicating paint was then applied to the part which dissolves when the part achieves the target temperature. It took 75 seconds to heat the assembly to temperature. The frequency was set to 255 kHz.

As was noted earlier, quality and repeatability were their top two concerns, and induction excels in both of these areas when compared to a torch. A torch doesn't offer the same level of repeatability and is highly dependent upon the operator's skill level. Consequently, quality can be variable with a torch. Induction offers other benefits, including safety (no open flame) and often speed.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...