Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

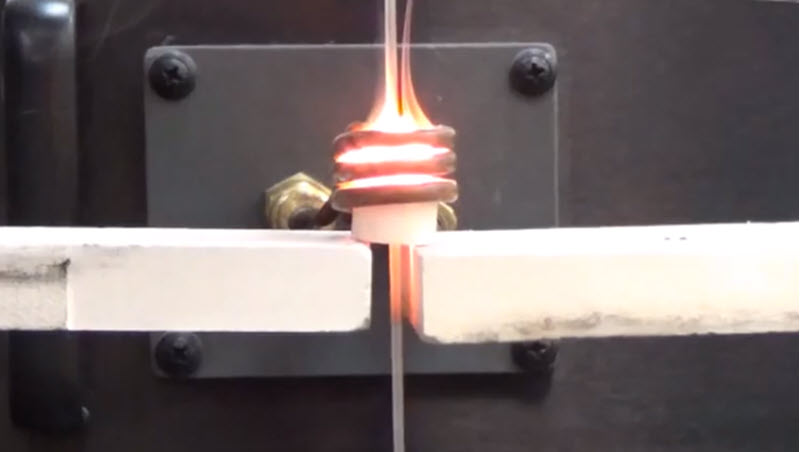

A client needed to heat a steel susceptor in order to heat glass rods for a glass cutting application. They decided to take advantage of free parts testing from THE LAB at Ambrell. Given their requirements, Ambrell's team of application engineers determined that an Ambrell EASYHEATTM 1.2 kW, 150-400 kHz induction heating power supply with a custom-designed single position multiple-turn helical coil would be the optimal solution for this application.

Initial tests were conducted to optimize the power delivered to the part. A pyrometer was used to measure the temperature of the part until it reached the target temperature. It was observed that it took eight seconds to heat the sample to 2000 °F (1093 °C) and melt the glass. This met the client's objectives.

THE LAB confirmed the viability of this application. Induction offered fast, safe and repeatable heating that would work well for susceptor heating for glass cutting. To learn more about free induction heating testing by our expert induction heating application engineers, visit our website. Or click the image below to check out application notes from THE LAB.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...