Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A client from the aerospace industry came to THE LAB looking to heat graphite discs of variable sizes. They needed to heat the discs to 200 °F (93 °C). This was a new process for the customer and they wanted THE LAB to help them prove out their application.

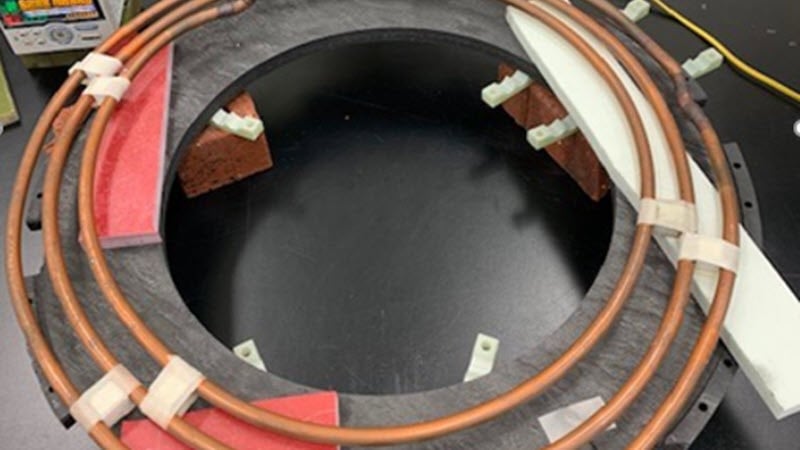

The LAB determined that an EKOHEAT® 45 kW, 50-150 kHz induction heating system with a custom-designed single position multiple-turn pancake coil would be the optimal solution for their application.

Initial tests were conducted to optimize the power delivered to the part. The coil was held 0.5” (12.7 mm) above the top surface of the part. Thermocouples were attached to the top and bottom surfaces of the part. It took 45 seconds to heat the sample to the target temperature of 200 °F (93 °C) on the surface closest to the coil. The surface farther from the coil reached 180°F (82 °C) in this time. It is possible to use closed-loop temperature control with the EKOHEAT to bring the top surface to temperature and hold it while the farther surface is brought to temperature.

Induction heating offers several benefits when compared to other heating options. Induction heating is extremely precise, consistent and repeatable. It's also very controllable, which is critical to this application. It's fast, so it can lead to a reduction in process time. It also saves energy when compared to many other heating processes.

Click here to learn about other heating application processes that THE LAB at Ambrell has designed. And, if you have an application you'd like tested, contact THE LAB to take advantage of complimentary induction heating application testing from our expert applications team.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...