Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

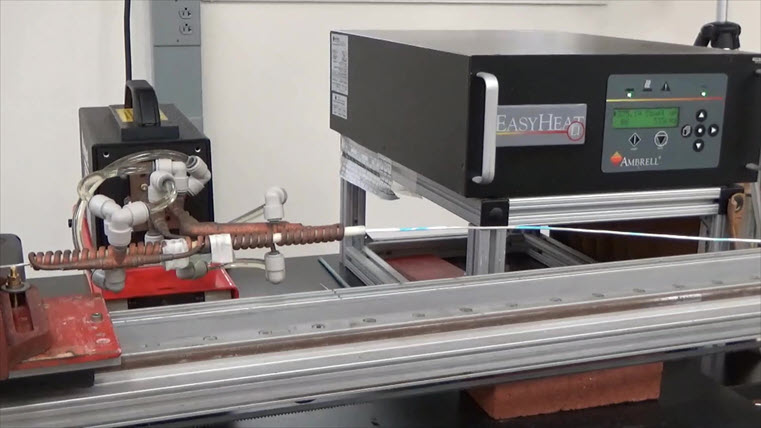

A client contacted THE LAB at Ambrell looking to heat copper wire to 500 °F (260 °C) for a wire heating application. They had been using induction heating, but wanted to upgrade to a modern induction power supply. THE LAB determined that an Ambrell EASYHEATTM 10 kW, 150-400 kHz induction heating system with a custom-designed single position multiple turn helical coil would work optimally for their wire heating application.

Initial tests were conducted to optimize the power delivered to the wire. Temperature indicating paint was then applied to the wire, which dissolves when the wire reaches target temperature. In static tests, it was observed that it took 2.5 seconds to heat an 11” (279 mm) length of sample wire to temperature. This corresponded with the desired feed rate of 21 feet (6.4 m) per minute (FPM). The speed was programmed to be 23 FPM (7.0 m) during testing to allow for an extra measure of confidence in its feasibility.

Induction offers a number of benefits for wire heating applications. First, induction is fast and highly repeatable. Consequently, it can boost throughput and quality. Additionally, induction can be easily integrated into production lines, especially when you consider the workhead can be placed away from the power supply. Finally, induction heating is also very energy efficient, resulting in additional cost savings.

Ambrell offers induction heating expertise based on over 30 years industry experience. To learn about more induction heating applications, including other wire heating applications, visit the Induction Applications section of our website. We also encourage you to fill out a lab service request form so the experts at THE LAB at Ambrell can test your application and recommend an optimal solution for your process.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...