Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

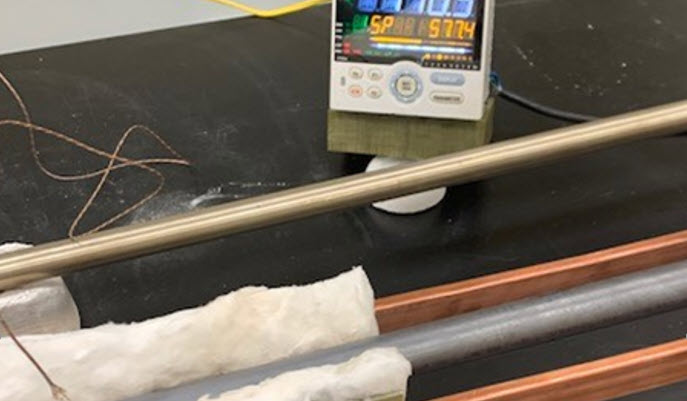

A battery manufacturer approached THE LAB at Ambrell with a pipe heating application. They had been using resistance heating, but it took 15 minutes to heat their pipe to their target temperature of 850 °F (454 °C). Their application involved heating magnetic and non-magnetic steel pipes for a casting system.

Visit our induction heating page to get a sampling of additional general induction heating applications assessed by THE LAB.

THE LAB determined that an EKOHEATⓇ 15 kW, 50-150 kHz induction heating power supply with a single position channel coil would be the right solution for their needs. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to the part, which dissolves when the part reaches temperature. For both the magnetic and non-magnetic steel pipes, it took 150 seconds to heat the sample to temperature. A thermocouple was welded to each part and heated from room temperature to verify the test results. Each was heated to temperature in less than 3 minutes.

For this client, speed to temperature was a considerable benefit, as was THE LAB's expertise in designing a solution that met their requirements. Other benefits include repeatability, as you get the same exact result each time with induction, energy efficiency, as only the portion of the part that requires heating is heated, and footprint, as induction and its movable workhead require less space that methods like oven heating.

THE LAB at Ambrell has considerable experience with induction heating applications of virtually all varieties. And, to learn more about free application testing, visit our page on THE LAB or contact us today to get the process started.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...