Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

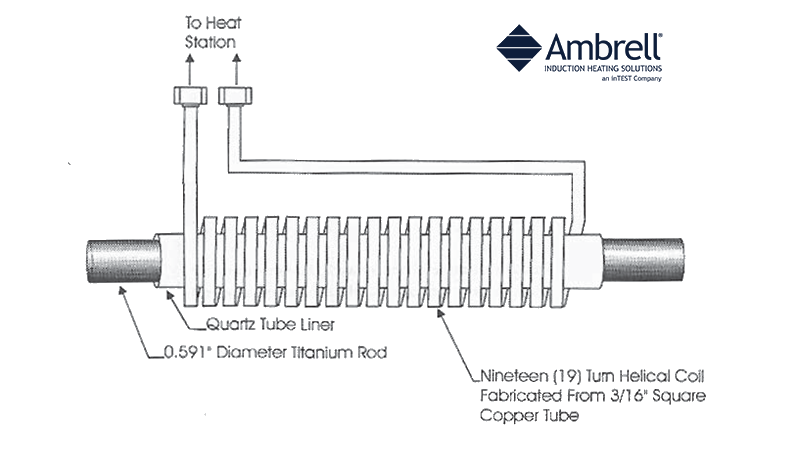

About:

A company in the turbine industry needed to heat titanium rod blanks prior to forging them into turbine blades. Heating needed to occur in a very precise fashion. The blanks had to heat to 2,030 ºF (1,110 ºC) with a tolerance of plus or minus 25 ºF (-3.9 ºC) with uniform heat from the surface to the core. THE LAB at Ambrell determined that an EKOHEATⓇ 20 kW, 50-150 kHz induction heating power supply with a workhead and nineteen-turn helical coil specifically designed for this application would meet this application's requirements.

An EKOHEAT 20 kW output solid state induction power supply, an optical pyrometer, 4-20 mA input, and a 19-turn helical coil were found to achieve the following results:

A temperature of 2,030 ºF (1,110 °C) was reached in 25 seconds with a 3 ºF (-16.1 °C) overshoot and stabilized at ± 2 ºF (-16.7 °C).

A time to temperature of 15 seconds could be achieved with this setup if run at full power.

Speed and precise heating were the primary reasons the client took advantage of free application testing from THE LAB at Ambrell. Efficiency was another consideration, as the efficiency of induction also resulted in energy savings for the client. Finally, process repeatability was another considerable benefit. Induction heating from Ambrell was able to deliver faster heating that improved throughput while enhancing end product quality.

Visit our induction forging applications page to review additional forging application notes from THE LAB at Ambrell. And, if you have an application that might benefit from induction heating, be sure to take advantage of complimentary application testing from THE LAB. We offer Virtual Lab Service. It allows you to view testing live from our induction application laboratory in the convenience of your office. Contact us today to get started.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...