Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

10/19/15 5:28 AM

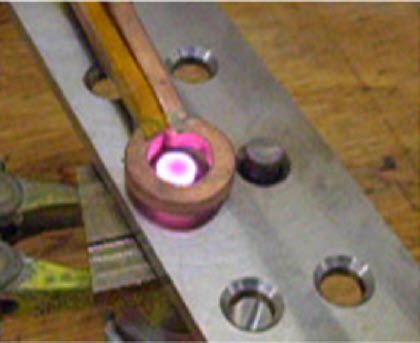

Rivet heating prior to head forming and hot heading is a popular application in the turbine manufacturing industry. A UK manufacturer of turbines for maritime vehicles wanted to switch to induction heating and contacted THE LAB at Ambrell for an application test on steel rivets.

The customer wanted to achieve maximum production efficiency with heat cycles of 10 seconds per rivet, with the end temperature of 700 ºC (1292 ºF). Ambrell’s application engineers tested this rivet heating application in THE LAB, and recommended a 4.2 kW EASYHEAT system for the customer.

Due to the small size of the induction heating system and remote work head, an EASYHEAT was an ideal candidate for inline production. Applying induction heating allowed the customer to enjoy the following benefits: repeatable and fixed heat cycles, precise heating (only the head of the rivet was brought to temperature) and increased production efficiency. Additionally, induction heating is flameless, which improved workplace safety significantly at the same time.

Ambrell offers induction heating expertise based on over 30 years of industry experience. We offer numerous insights into fastener heating in our Fastener Heating Brochure. We also encourage you to fill out a lab service request form, which is free, so that we can test your application and recommend an optimal induction heating solution for your heating application.

Check out our extensive induction heating video library, and maybe you will see a process just like yours tested by our induction heating experts in THE LAB.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...