Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

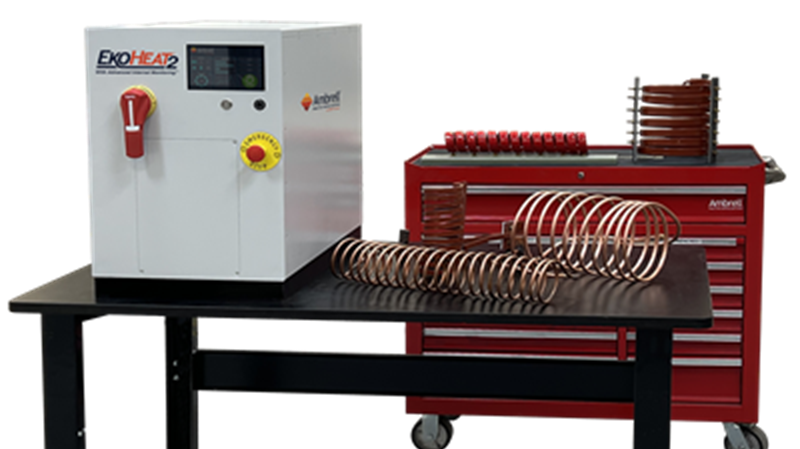

Ambrell, an inTEST company, has just unveiled the EKOHEAT 2, an exciting leap forward for induction heating. This innovative next-generation line of induction heating systems builds upon the success of its predecessor. These enhancements boost process accuracy, reduce system cooling requirements, and support client work with a new control panel and suite of diagnostics and guides.

The EKOHEAT 2 is equipped to analyze internal system temperatures and pressure, enabling preventive steps.

Using an innovative design architecture, EKOHEAT 2 has 30% fewer internal plumbing connections than previous designs, therefore 30% less chance for leaks.

State-of-the-art processors, dedicated to tuning the frequency of the coil for optimum performance even under heavy loads, and to executive operations such as IoT, Industry 4.0 data collection, control, and monitoring.

An HTML-based user interface allows the interface to appear on remote devices that have wired ethernet connections to the same Local Area Network the generator is on.

All EKOHEAT 2 systems also include Advanced Internal MonitoringTM. This important feature-set closely checks and reports on key internal power supply component temperatures, employs parallel resonance, offers true high-resolution RF power control, and incorporates state-of-the-art processors, dedicated to tuning the frequency of the coil for optimal performance and rapid data collection.

EKOHEAT 2 systems also have analog monitoring capability, remote monitoring and data collection, and customer communication capability. Want to learn more about the EKOHEAT 2 and its featured set, including Advanced Internal Monitoring? Visit our website and download our new brochure.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...