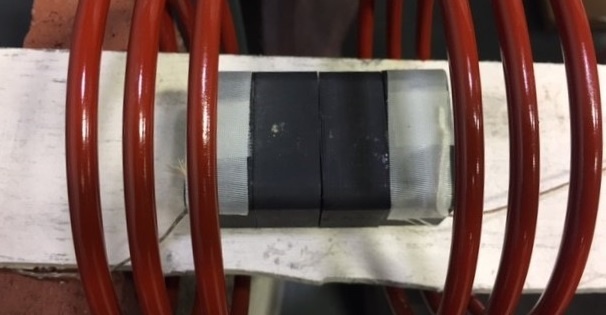

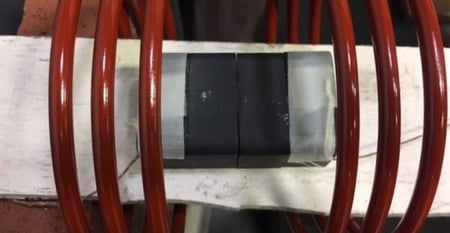

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

This application involved heating four steel laminate parts (c-lams) for a pre-heating application in the automotive industry. The parts, which are inserts, are heated simultaneously before robotic pick-and-place for plastic overmolding. The client was looking to change to induction from resistance heating.

An EKOHEAT 15 kW/50-150 kHz system was chosen for this application. A thermocouple was attached to the top surface of each outer c-lams in the stack for temperature monitoring. The parts were successfully heated to the target temperature of 190°C (374 °C) within 10.0 seconds with the EKOHEAT, which met the client's objective.

Speed, repeatability and energy efficiency led the client to consider induction heating over resistance heating. The guidance and expertise from THE LAB at Ambrell was another critical factor in their decision. To learn about other preheating applications evaluated by THE LAB at Ambrell, visit our website.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...