Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

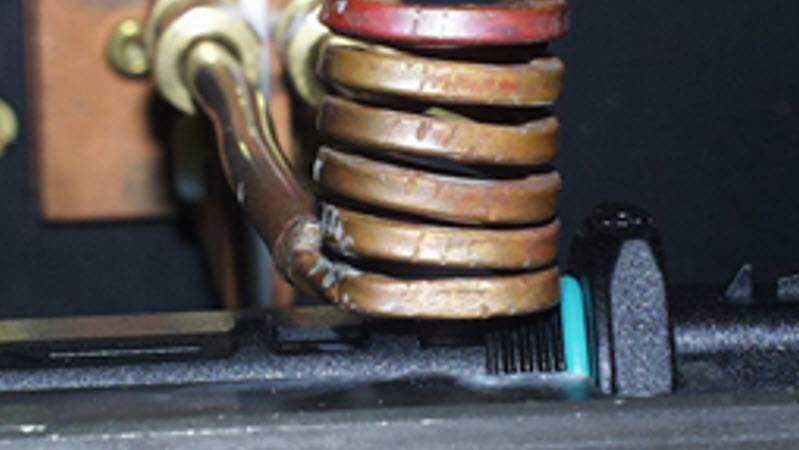

THE LAB at Ambrell tested an induction heating application involving heating a solder joint to reflow the solder on a circuit board evenly. The end product was a diesel fuel tank component. The target temperature for the application was 482º F (250º C) and THE LAB determined that an EASYHEAT™ 10 kW, 150-400 kHz induction heating power supply was the right solution for this soldering application.

A multiple-turn helical coil was designed to ease loading and unloading. Additionally, there were sensitive electrical components near the heating area that could not be heated, which was taken into account during process development. In order for the solder alloy to wick and run the length of the overlap area, flux was applied to the solder location. It took 2.5-3 seconds to achieve the target temperature. The heating was very uniform and there was no overheating.

Using induction for soldering offers a number of benefits. Speed, precision, repeatability and safety are among them. Once the process is determined, you can count on getting the same result every time. In this case, repeatability and the resulting enhanced product quality were the key factors that led to their decision to switch to induction. It's difficult to match the speed and repeatability of induction when using a soldering iron.

This soldering application is just one example of the many applications that THE LAB at Ambrell handles on a regular basis. You can explore a full range of application notes from various industries on our website. And, of course, you are welcome to send in your parts for free testing. You'll receive a report and video after testing, and you can even view the testing live with our new Virtual Lab Service.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...