Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

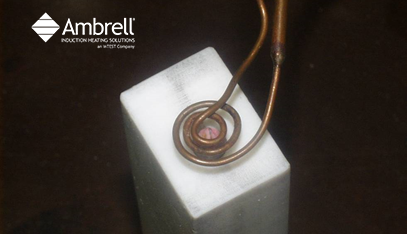

THE LAB at Ambrell tested an induction heating application involving soldering fabric to a Kovar tip assembly. An Ambrell EASYHEATTM 1.2 kW, 150-400 kHz induction heating system equipped with a remote workhead and three-turn pancake coil specifically designed for this application was determined to be the right solution for this soldering application. The target temperature was 300 ºF (149 ºC) and the system frequency was set to 242 kHz.

The three-turn pancake coil was used to heat the tip of the cone to 300 ºF (149 ºC) in 2-3 seconds. The coil design allows for easy placement of the fiber across the tip of the cone and reduces the heat flow to the bottom of the assembly for the manufacturing process. The timing and quality met the client's objectives.

Using induction for a soldering application like this one offers several benefits. Speed, precision, repeatability and safe, flameless heating are among them. Once the process is determined, you can count on getting the same result every time. It's also hands-free, which not only boosts repeatability with there being less dependence on operator skill but worker safety too. In this case, repeatability and the resulting enhanced product quality were the key factors that led to their decision to switch to induction.

This is just one example of the many applications that THE LAB at Ambrell handles on a daily basis. You can explore a full range of application notes from various industries. And, of course, we welcome you to send in your parts for free testing. Be sure to ask about our new Virtual Lab Service offering, where you can observe testing live from the comfort of your office.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...