Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

In the last post, we discussed some of the basic historical milestones responsible for the modern induction heating machines and technologies we have today. However, the potential of induction heating capabilities are far from limited. Here's where experts think the future of induction heating is headed.

An induction heating system typically consists of three parts: the power unit, the workhead, and the work coil. The demand for induction heating, induction hardening, induction melting, induction forging, and other induction applications is most certainly increasing. This is because induction equipment continues to evolve and systems are available that have been highly engineered to optimize client processes. The versatility and other unique properties of induction enable both designers and engineers of many areas of specialty to use induction as a secure and reliable method of heating.

In addition to the improvements made for induction equipment and other induction materials, induction remains among the most popular and relied on form of heating, and its processes are optimized every day. For the foreseeable future, it will be seen as a form of cutting edge technology that's absolutely essential to the further research, discovery, and development of similar processes in the future that may be even more effective.

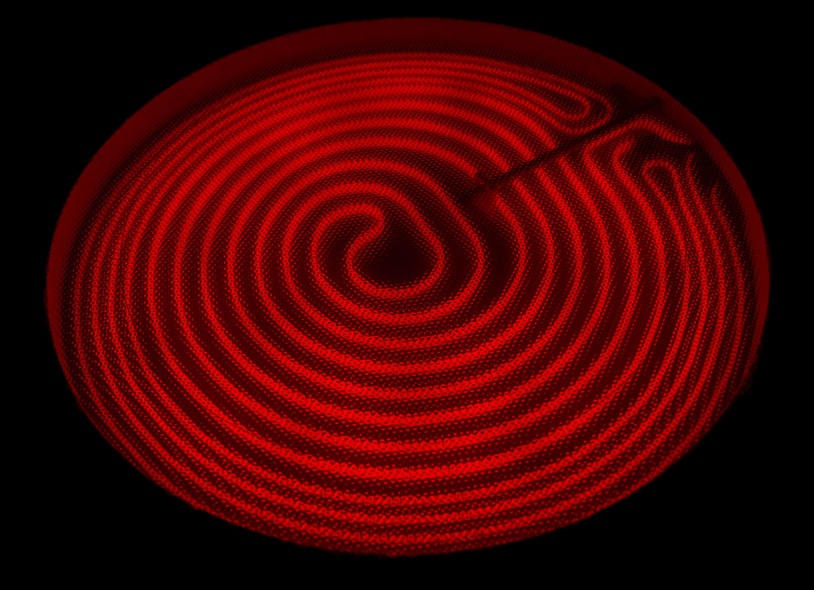

The phenomenon of induction and its many useful applications are clear. Keep in mind that the efficiency of an induction heating system for a specific application continues to depend on four factors: the characteristics of the part itself, the design of the inductor, the capacity of the power supply, and the amount of temperature change required for the application. While basic principles like these never change, the induction heating industry will continue to evolve as new technologies and processes are developed. While most consumers only know induction heating from their electric stove tops, manufacturers are increasingly relying on induction equipment to make their parts in a fast, repeatable and energy efficient manner.

Ultimately, the sky's the limit when it comes to finding suitable applications for induction, and THE LAB at Ambrell can help you determine if your process is a fit. However, being aware of where the technology started in addition to where experts think it's going is the key to using it as efficiently as possible in the years to come. For more information about induction heating and brazing equipment, contact Ambrell Corporation.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...