Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

12/12/22 7:20 AM

An engineering firm had a new process that required the removal of a coating of insulation. It was important not to heat the material up too much, as the tin-coated copper might then melt. They turned to THE LAB at Ambrell to develop a solution that met these requirements.

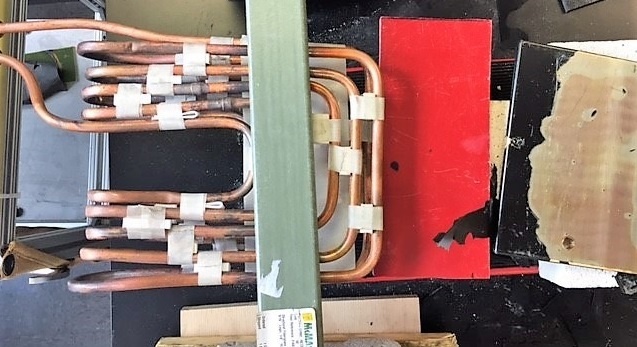

More induction bonding application notes

THE LAB determined that an EKOHEAT® 50 kW, 15-45 kHz induction heating system would work well for this application. They designed a single position multiple-turn channel coil. A 7.5" x 4.5" (191 mm x 114 mm) area of the tin-coated copper required heating. After applying temperature indicating paint to the part, it took 35 seconds to heat the sample to temperature. The coating was then removed from the tin-coated copper plate. Heating longer length bars would increase the heating time by 10-15 seconds due to conduction losses.

THE LAB confirmed the viability of the application as the part heated quickly for coating release without melting the tin-coated copper. Precise, targeted heating prevented overheating of the material, which was critical for this application, while its repeatability meant there wasn't any risk of operator error leading to overheating. The expertise of THE LAB was also critical to ensuring the success of this coating removal application.

To learn about additional applications tested by THE LAB at Ambrell, visit our website. And, be sure to reach out to THE LAB should you have any application questions.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...