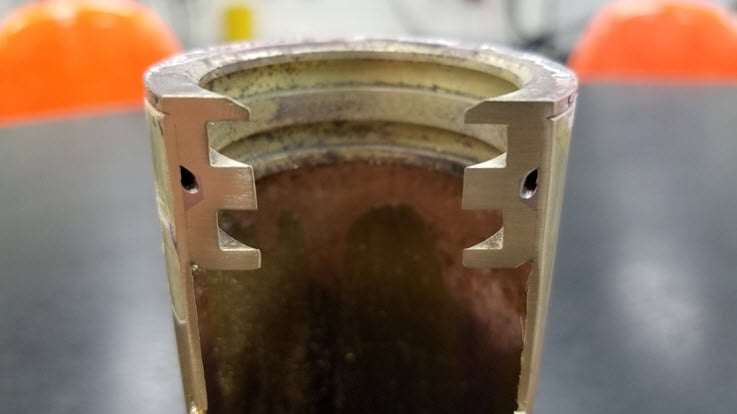

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A manufacturer of sink products had been using a torch for brazing brass assemblies. However, repeatability had become an issue so they turned to THE LAB at Ambrell to test induction heating for their brazing application.

More brazing application notes

THE LAB determined that an EASYHEAT™ 6 kW, 150-400 kHz induction heating system with a custom-designed single position multiple-turn helical coil would be the right solution for their brazing application. It took two minutes to heat the 2”/51 mm OD brass assembly to 1425 °F (773 °C), meeting the client's time objective.

As already mentioned, repeatability was a critical factor as to why they turned to Ambrell induction heating. The client was seeing inconsistencies from torch operator to operator, so switching to induction resolved that issue. Induction was also fast, and it doesn't introduce a flame into the work environment, making it more comfortable and safe.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...