Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A fastener manufacturer contacted THE LAB at Ambrell as they needed to preheat steel wire prior to hot heading. The end products were screws. They wanted to heat steel wire to 350 °F (177 °C) within seconds. They turned to induction because they wanted to increase tool life with hot heading, as cold heading is harder on tooling.

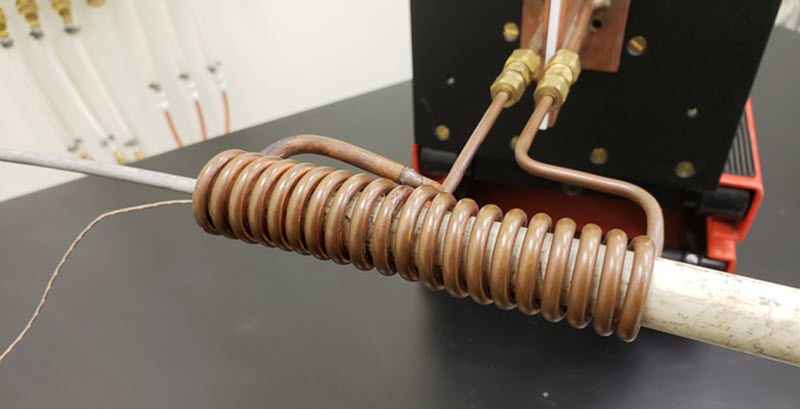

An Ambrell EKOHEATⓇ 30 kW, 50-150 kHz induction heating power supply with a custom-designed single position multiple-turn helical coil were used for this application. After initial testing to optimize the power delivered to the part, temperature indicating paint was then applied. A thermocouple was also used to monitor temperature. The power was turned on for 0.5 seconds, which simulates the client's run rate. It was observed that the wire heated well to maintain the target temperature after three seconds, which is the time required for the wire to travel from the induction coil to the cutoff location.

As already mentioned, cold forming can take its tool on tooling, which is a primary reason this client looked to induction heating. Induction reduces pressure on the die and extends die life. Induction is well-suited for high volume assembly lines, which is another benefit of induction for this fastener hot heading/heating application. And, of course, induction's repeatability is also important as it ensures quality. The client was also appreciative of the expertise from the engineers at THE LAB at Ambrell.

Visit our fastener manufacturing page to see additional fastener-specific application notes. And, if you have an application you'd like assessed, contact THE LAB to take advantage of complimentary induction heating application testing from our team of induction application experts.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...