Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

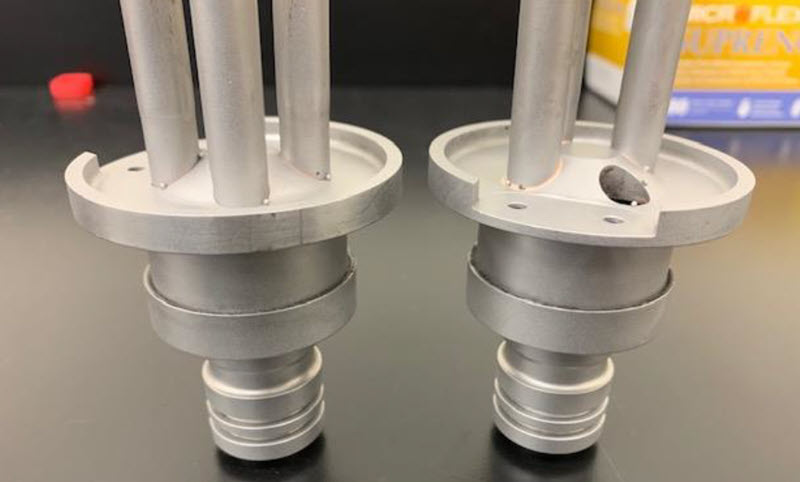

An aerospace client approached THE LAB at Ambrell with a brazing application. They tried using an oven and a torch for brazing their steel nozzle assembly, but were seeing inconsistent results. This was a low volume application, so heating time wasn't a concern. However, the location of the desired braze joint was shielded from the induction field by the lip of the nozzle, which complicated the process.

More Brazing Application Notes

THE LAB determined that an EASYHEAT™ 4.2 kW, 150-400 kHz induction heating power supply with a single position multiple-turn helical coil was the right solution for this application. It was decided that the only way to form the braze joint was to heat the assembly together despite the shielded area. The joint area and surface were coated in black flux. The provided braze rings were used. Heating took six minutes, which was long enough that the heat conducted to the joint area to melt the braze alloy ring and form the joint.

For this client, it came down to repeatability as it proved elusive with both a torch and an oven. Work environment was another significant benefit. Induction doesn't have an open flame like a torch, while it also introduces less heat into the work environment as there is no ramp up time like with an oven. Finally, induction requires a minimal amount of floor space, even less when you consider the workhead can be placed a considerable distance away from the power supply.

While THE LAB has a wealth of experience across numerous applications, induction brazing is our most popular one. To learn more about free application testing, visit our page on THE LAB or contact us today to get the process started.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...