Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

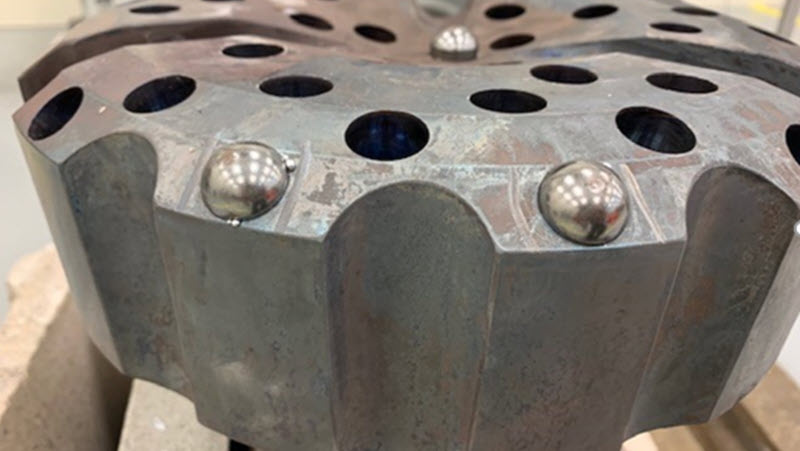

A client in the oil and gas industry came to Ambrell with a shrink fitting application. They had been using a cold method for inserting carbide buttons into hammer bits, but wanted to look to induction heating. They took advantage of THE LAB at Ambrell's complimentary applications testing to determine the feasibility of their shrink fitting application.

The client needed to heat hammer bits to 500 °F (260 °C). THE LAB determined that an Ambrell EKOHEAT® 50 kW, 5-15 kHz induction heating power supply with a workhead and coil specifically designed for this application would be the right solution for this application. They designed a single position multiple-turn pancake coil and used an infrared camera for temperature monitoring during testing.

The large drill head was then ready for testing. THE LAB found that the outer area of the part heated more quickly than the center. Power delivered to the part was adjusted to keep the maximum temperature between 570° F (299° C) and 580° F (304° C) while the center came up to the target temperature through induction and conduction. Once at temperature, the carbide bits were then inserted into the hammer bit.

Torch heating is sometimes also used for this application, but induction offers several benefits. Speed is a significant one. Induction also is more efficient as it heats directly into the part. Finally, induction does not introduce an open flame into the work environment, so it results in a safer and often cooler work place.

THE LAB at Ambrell has considerable experience with induction shrink fitting applications like this one. Visit our induction shrink fitting page to see a sampling of shrink fitting applications assessed by THE LAB. And, to learn more about free application testing, visit our page about THE LAB or contact us today to get the process started.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...