Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A company that manufactures medical devices needed to heat stainless steel braids for an annealing application. This is a new application for the client and it is part of a high-volume production process. The stainless steel braids needed to be heated to 1,000 °F (538 °C) in just seconds.

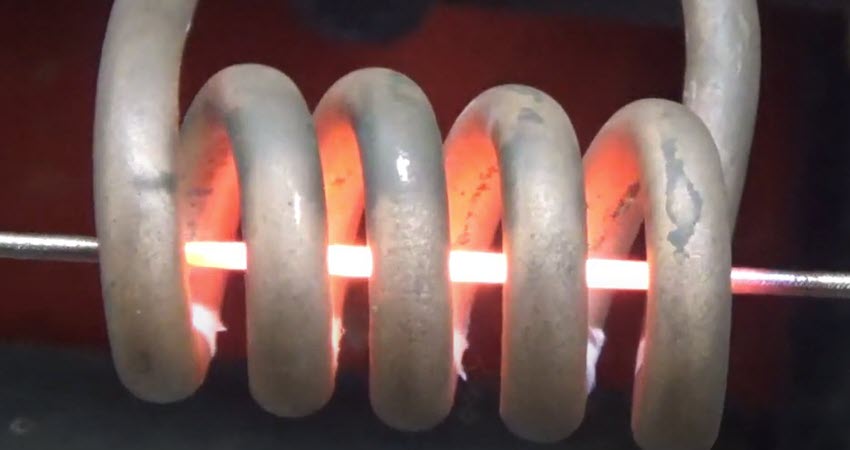

More annealing application notes

THE LAB at Ambrell determined that an Ambrell EASYHEAT 6.0 kW, 150-400 kHz induction heating system was the right solution based on their application requirements. They also built a custom-designed multiple-turn helical coil. Initial tests were conducted to optimize the power delivered to the part. Once a satisfactory heat pattern was achieved in the time-frame allowed, samples were run at multiple settings. Heating took just 2-5 seconds depending on the sample used, meeting the client’s requirements.

There were several reasons why the client was interested in induction heating for their annealing application. Speed was a major factor, and the time-to-temperature was just seconds. Induction also requires minimal floor space, and the fact a workhead can be placed away from the power supply can also help when considering any integration. It is also a high repeatable heating method, which is ideal for a high volume application such as this one. Finally, induction is highly efficient as it's instant on/off, making it a greener choice that can result in energy savings.

THE LAB at Ambrell has tested numerous annealing applications. Learn about free applications testing, or click the image below to check out other annealing application notes.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...