Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

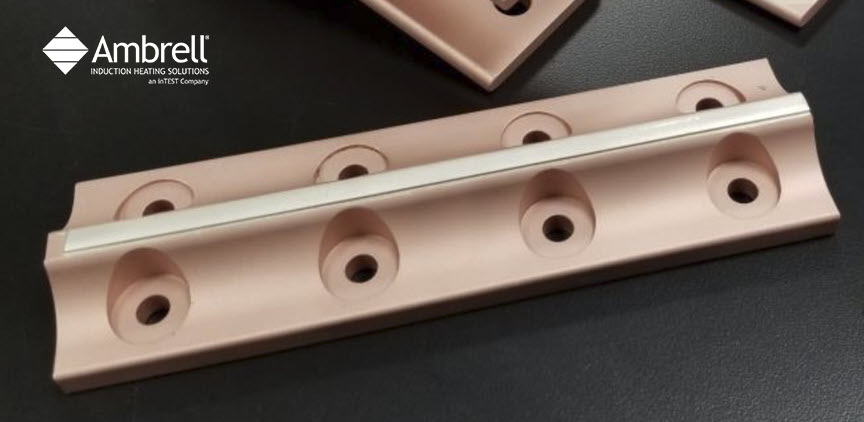

A client in the high voltage contracting business wanted to move away from flame heating, so they turned to THE LAB at Ambrell. They needed to heat four types of copper busbars for a brazing application. The target temperature was 1,400 °F (760 °C). THE LAB determined that an Ambrell EKOHEAT® 30 kW, 50-150 kHz induction heating power supply with a custom-designed single position multiple-turn helical coil would meet their objectives.

Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to the part, which dissolves when the part reaches target temperature. All four styles of parts were individually heated using the same power supply settings. The 5” and 7” (127 and 178 mm) long copper busbars took one minute for the braze to flow. The 0.25 inch (6.4 mm) thick bent copper busbar saw the braze begin to flow at 1.5 minutes and the 0.25 inch (6.4 mm) thick straight copper busbar saw the braze begin to flow within 1 minute. These results met the client's objectives.

The client chose induction heating for a number of reasons. Induction heating's speed was one considerable benefit. It's also highly precise and repeatable, which is a significant benefit when compared to a torch. There is also no open flame, which results in a safer working environment and was a primary factor in their decision. Finally, the expertise of THE LAB was critical as they validated the feasibility of the application and designed a solution that met their requirements.

Take a look at our induction brazing page to see a variety of brazing applications across numerous industries. If you have an application you'd like assessed, contact THE LAB to take advantage of free induction heating application testing from our expert application engineering team. We now have remote testing from our application lab, so you can observe testing live from the convenience of your office.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...