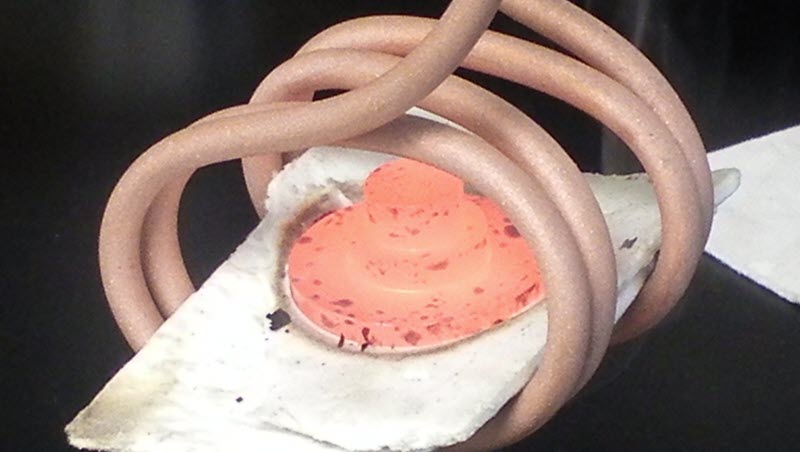

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A customer had been using an offline oven, but instead wanted the heating to occur within a cell and decided to assess induction as a solution. The application involved heating a Nickel-flanged part (a mold) for a preheat prior to welding application. THE LAB at Ambrell determined that an Ambrell EKOHEAT 15 kW induction heating system with a single position multiple-turn oval coil would be the right solution for the application.

Initially, a helical coil design was tested which did heat the part faster, but the pattern wasn’t uniform. With the oval coil and an EKOHEAT induction heating system (frequency was set to 84 kHz), the heating time was 45 seconds and a uniform heating pattern was evident. The speed and heating pattern met the client’s objectives.

As mentioned above, the client was looking to integrate heating into their cell/process, and induction is a great fit because the workhead can be placed away from the power supply and the overall system is smaller than an oven. This induction solution was also able to achieve the client's heating time objectives and, also important to note, induction is a highly repeatable process.

To read other application notes from THE LAB at Ambrell, visit our heating applications page. If your process might benefit from induction heating, be sure to take advantage of free induction heating applications testing from our expert application engineers.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...