1 min read

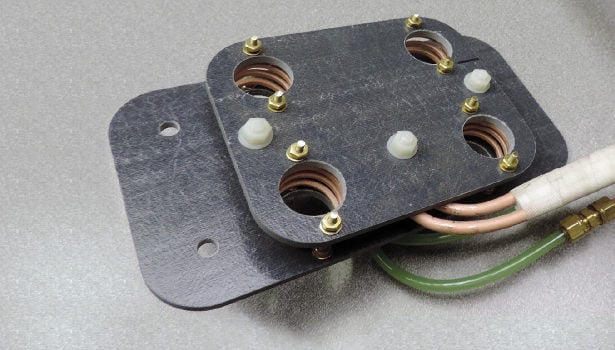

Induction Heat Staking Steel Inserts

Objective A supplier of automotive parts needed to heat steel inserts to be placed into a plastic...

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Objective A supplier of automotive parts needed to heat steel inserts to be placed into a plastic...

4 min read

Injection-molded plastic parts are used increasingly in industry, particularly automotive, because...

1 min read

Heat staking, also known as metal-to-plastic insertion or indirect induction heating, involves...

1 min read

Our newly updated design guide, titled the Heat Staking Design Guide: Inserting Metal into Plastic...

1 min read

A client came to THE LAB at Ambrell needing to heat a 0.85” (21.6 mm) outside diameter magnetic...

1 min read

A client came to THE LAB at Ambrell with a heat staking application involving heating a knurled...

1 min read

Objective A manufacturer in the medical industry came to THE LAB at Ambrell with a heat staking...

1 min read

A pallet manufacturer needed to heat magnetic steel to 300 ºF (149 ºC) for insertion into a...

1 min read

An company came to THE LAB at Ambrell needing to insert brass threaded inserts into seven locations...

1 min read

An organization had been using a torch for this metal-to-plastic insertion application involving...

1 min read

A supplier to an engine manufacturer needed to heat magnetic steel inserts for a metal-to-plastic...

1 min read

A supplier to the automotive industry was looking to heat a cooling fan shaft for a...

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service