Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

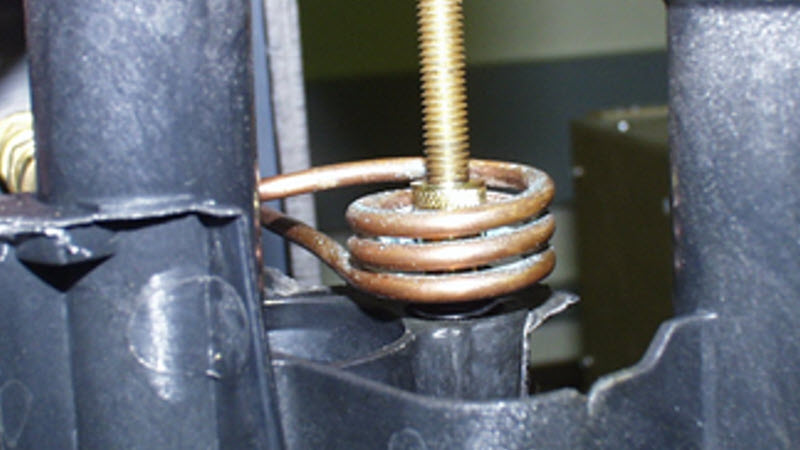

An company came to THE LAB at Ambrell needing to insert brass threaded inserts into seven locations on a plastic thermostat housing. THE LAB determined that an Ambrell EASYHEATTM 3.5 kW induction heating system would be the right solution for their heat staking application. Three different coils for varying patterns were designed by Ambrell's team of applications engineers and used during testing.

A three-turn oblong coil was used to heat two brass inserts in close proximity. The inserts are heated in the coil above the insertion hole for 10 seconds to reach 700 ºF (371 ºC). The inserts are then pushed into the holes for placement. The second hole pattern requires a two place, three turn coil and the third pattern requires a three place, three turn coil. All three applications reached 700 ºF (371 ºC) in 10 seconds and can be heated using three 3.5 kW EASYHEAT units.

Induction heating offers several benefits when compared to methods such torch heating. Speed can be one factor. Additionally, precision and repeatability are considerable benefits, as induction delivers consistent results every time while a torch is dependent on the operator. This was a considerable benefit to this client. Induction can also enable simplified fixturing, as it did here. Finally, eliminating an open flame in the work environment enhances safety in the workplace while also introducing less heat into the work environment.

To read other metal-to-plastic (heat staking) application notes from THE LAB at Ambrell, visit our metal-to-plastic insertion applications page. And, if you have a heating application that would benefit from free parts testing from THE LAB, fill out our parts testing form to get the process started.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...