Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A manufacturer of pistons approached THE LAB at Ambrell with a shrink fitting application. They had been using an inexpensive portable induction unit, but found it unreliable for their application. Their application involved heating magnetic steel pistons for shrink fitting onto a chrome shaft. The target temperature was 1,100 °F (593 °C).

Visit our induction shrink fitting page to get a sampling of additional shrink fitting applications assessed by THE LAB.

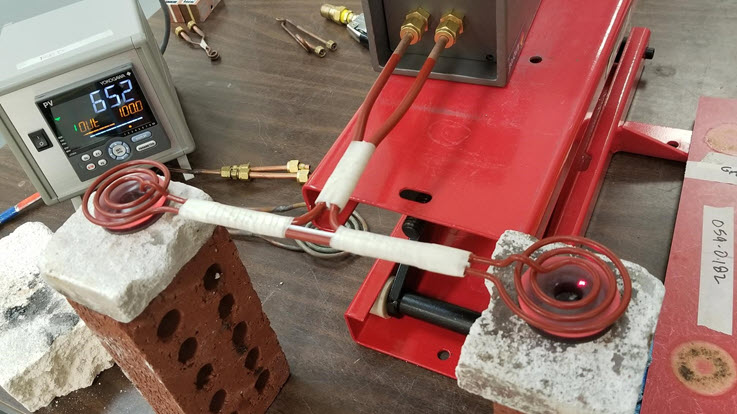

THE LAB determined that an EASYHEAT 2.4 kW, 150-400 kHz induction heating power supply with a single position multiple-turn pancake coil would be the right solution based on their requirements. Initial tests were conducted to optimize the power delivered to the part. An optical pyrometer was used to monitor one of the pistons as the two were heated. The pistons were heated with a small gap between the part and the induction coil. The pistons reached 1,100°F (593 °C) within one minute.

For this client, getting a repeatable, reliable result drove the desire to switch to Ambrell. The handheld unit they were using wasn't delivering the required results, and THE LAB was able to offer a solution that would deliver great results every time. When compared to other heating methods for shrink fitting, induction's benefits include its speed along with its localized, repeatable and non-contact heating.

THE LAB at Ambrell has a wealth of experience with induction shrink fitting applications. And, to learn more about free application testing, visit our page on THE LAB or contact us today to get the process started.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...