Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

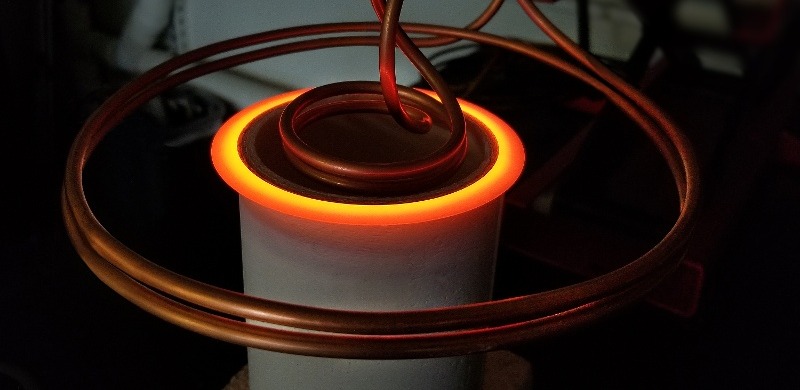

Annealing is a process where heat is applied to a material to increase its malleability and make it more workable. Or simply put, a metal is typically heated to a specified temperature and cooled, which results in a softened material that is more easily formed. Induction is one heating method that is commonly used for annealing.

Annealing with induction heating delivers several advantages over other heating methods such as flame including:

Induction is highly localized, which helps to ensure only the surface is heated

Induction delivers precise control

Induction doesn't require a great deal of space/footprint within a manufacturing facility

Induction annealing is used in a wide array of industries for a number of applications. Here is a sampling of applications:

Tubes/pipes (stainless steel, steel copper)

Bar and wire

Threads of hardened parts

Seam annealing

Full body annealing

Ammunition annealing (neck and body)

THE LAB at Ambrell has conducted numerous annealing application tests and dozens of application notes are available for your review. Some may be on an application just like yours. Complimentary application testing is also available from THE LAB.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...