Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

10/21/15 4:23 AM

Induction brazing is used in the joining of many different metals for numerous applications. Induction is a superior method of brazing due to its fast, efficient, flameless, non-contact heating. Typical joints are steel-to-steel, steel-to-brass, steel-to-copper, brass-to-copper, brass-to-copper, copper-to-copper, aluminum-to-aluminum, and copper-to-aluminum.

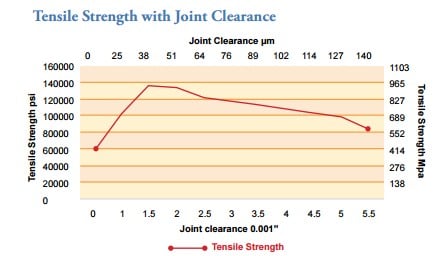

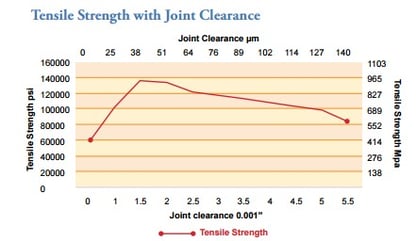

Design the joint correctly allowing for a 40µm (0.0015”) to 125µm (0.005”) clearance between the two surfaces at the braze material flow temperature – to allow for capillary action and joint wetting.

Clean the surfaces of the joint materials.

Apply flux to both pieces. Flux removes oxides from the base material while also preventing oxidation during heating.

Fixture the two pieces together with a braze ring or pre-form and position in the coil.

Heat the two pieces until both pieces achieve the braze material flow temperature and stick feed the braze material if pre-forms are not being used. (Our highly experienced applications lab will make sure the coil is designed to correctly heat your parts).

Clean the brazed joint and remove all of the flux residue.

More information on how induction heating is used in the brazing process is available in our Brazing Guide. We encourage you to read more about our induction brazing solutions in our brochure 'Precision Induction Brazing'.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...