Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

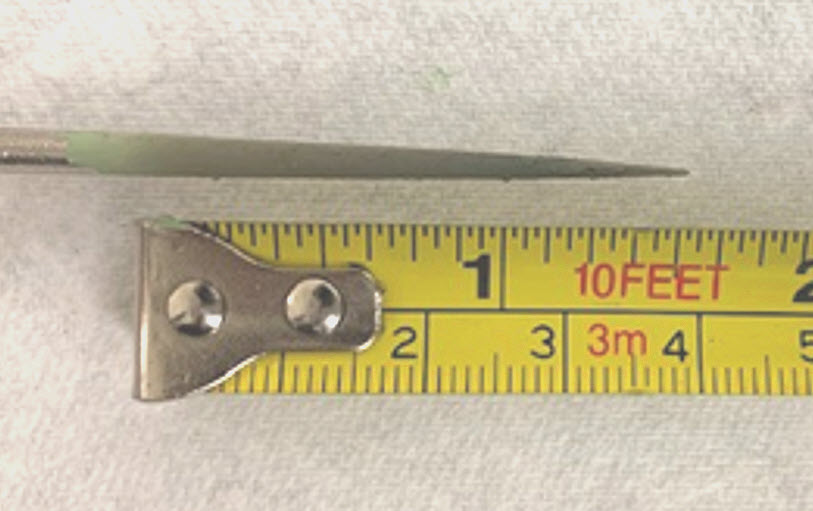

A client came to THE LAB at Ambrell looking to design a process to heat steel shafts for forming to manufacture medical tools. The client hadn't been using an alternative heating method, so this was a new application for them. The parts were stainless steel (magnetic and non magnetic) and nickel alloy and they needed to heat them to 800 °F (427 °C) for forming.

Visit our medical device manufacturing page to see other similar applications.

THE LAB determined that an Ambrell EASYHEATTM 6 kW, 150-400 kHz induction heating system would be the right fit for their requirements. A custom-designed single position multiple-turn helical coil was built to generate the required heating for this forming application. Initial tests were conducted to optimize the power delivered to each part. Temperature indicating paint was then applied to each part, which dissolves when the part reaches the target temperature. It was observed that each sample could be heated to temperature in 2 seconds. In fact, the magnetic stainless steel and nickel alloy steel parts could be heated to temperature in just 1 second.

Induction's rapid, precise heating played into the client's decision to leverage it as their heating method of choice. Additionally, induction is extremely repeatable, which makes it ideal for high volume manufacturing processes. Finally, induction, with a remote workhead, is extremely space efficient when compared to other methods like oven heating.

If you have an application you'd like tested, contact THE LAB to take advantage of free induction heating parts testing by our expert applications engineers. You can even leverage our newest offering called Virtual Lab Service, where you can experience lab testing live from the comfort of your home or office.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...