Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

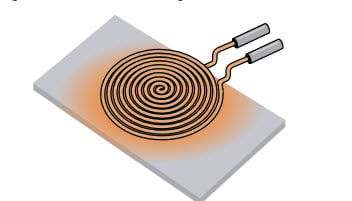

The induction work coil, also known as the inductor, is the component in an induction heating system that defines how effectively and efficiently the work piece is heated. A current flowing in a conductor creates a magnetic field. An alternating current creates an alternating field which produces an alternating current in a second conductor (your part or work piece).

The current in the work piece is proportional to the field strength. The transformer effect where the amount of current induced in the work piece is proportional to the number of turns on the coil and is generated as a mirror image of the work coil.

Of course, coil design is essential to the effectiveness and efficiency of any induction heating process. We design coils by first understanding where the heat needs to be generated in the part to perform the heating process, and then design the coil to achieve the heating effect. Induction coils are water-cooled copper conductors made of copper tubing that are readily formed into the shape of the coil for the induction heating process.

There are a wide array of coil designs available depending on your heating requirements and the shape of your part, ranging from helical coils to pancake coils to channel coils. Check out our Induction Heating Work Coils brochure to learn more and read our blog post on the 5 Basics of Induction Coil Design.

Remember, THE LAB at Ambrell offers complimentary applications testing, so you don't have to worry about coil design for your application. Let the experts at THE LAB make a systems recommendation that includes the optimal coil design for your process.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...