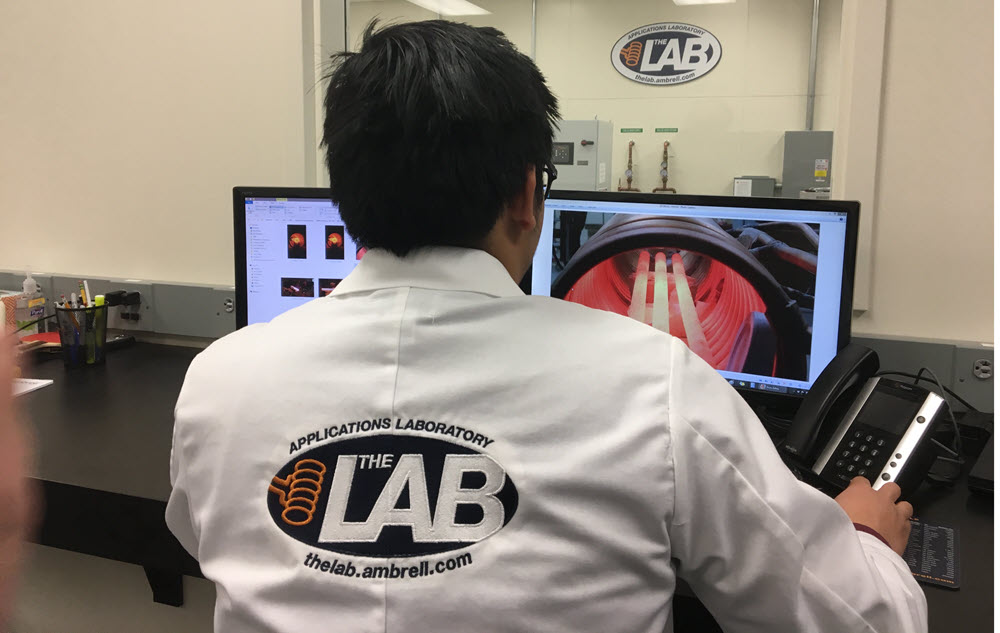

Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

Materials science is about understanding the intricate relationship between a material's structure and its properties. From the strength of steel to the conductivity of graphene, these insights are crucial for developing new and better materials for everything from airplanes, to automobiles, to artificial joints. But how do researchers heat and manipulate these materials for testing and analysis? Induction heating can be the answer.

Unlike traditional heating methods that use flame or resistance, induction heating uses a rapidly alternating magnetic field to induce current within a material. This current creates heat directly within the material itself, offering a unique set of advantages for materials research, including precise control, repeatability and speed of heating.

Here are some specific examples of how induction heating is used in materials research and testing:

Induction heating allows researchers to investigate a material's strength, ductility, and other mechanical properties at elevated temperatures, providing insights into their performance in various environments at different extremes.

Many materials undergo structural changes (phase transitions) when heated. Induction heating allows for precise control of the heating profile, enabling researchers to study these transformations in detail.

By rapidly heating and cooling materials under controlled conditions, researchers can explore new material compositions and processing techniques, paving the way for the development of next-generation materials with tailored properties.

Induction heating is a powerful tool that has become an essential for many materials scientists as they do research. By providing precise, clean, and versatile heating, it is helping unlock the secrets of materials and develop the materials of tomorrow.

Want to learn more about the benefits of induction heating in material science? Check out our recent blog post.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...