Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

Manufacturers in the aerospace industry face two primary challenges: advancing materials performance and application to deliver ever-increasing product quality. Induction is the preferred technology for shaping future material capabilities in the aerospace sector.

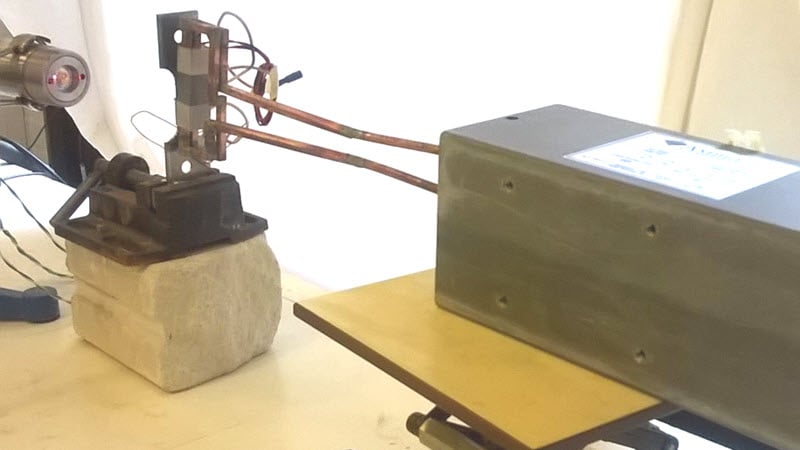

Ambrell's Lab Consultants have just performed a successful tensile test of stainless steel for a Swedish OEM aerospace manufacturer. The companies met at a major industrial trade show in Germany and discussed the opportunities for solving this material testing application. Our induction heating solutions were a great match due to their versatile frequency range. Below you can see the actual test set up. For improved process control, we decided to use an infrared pyrometer. 'This way, the customer not only has the advantage of precision heating, but can also measure the temperature accurately in this demanding process' said Fabrice Conraud, Ambrell's Lab Consultant.

Ambrell has been a trusted supplier to the aerospace sector for over 30 years. We have collected our industry expertise in this helpful library. There is a good chance that we have already solved a heating challenge similar to yours in one of our Application Laboratories worldwide.

Ambrell's application testing is free-of-charge and allows you to determine the feasibility of applying induction to your heating process. Simply fill out the form to see how your application can benefit from this innovative source of heat.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...