1 min read

Curing Material on an Aluminum Mandrel

Objective Heat a customer supplied aluminum cylinder to 80-120°C for a material curing application....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Objective Heat a customer supplied aluminum cylinder to 80-120°C for a material curing application....

1 min read

In today’s manufacturing landscape, efficiency, precision, and sustainability are critical....

1 min read

When it comes to many manufacturing processes, including this forging application, precision and...

1 min read

The busy fall tradeshow schedule continues, with Ambrell set to exhibit at two more events next...

1 min read

Toronto, ON | September 29 – October 2, 2025

1 min read

Ambrell Induction Heating Solutions will be exhibiting at two industry tradeshows in the coming...

1 min read

Objective A company needed to heat a 10 mm diameter steel wire to 400 °F (204 °C) in a continuous...

1 min read

A customer contacted THE LAB at Ambrell because they needed to solder a copper fuse assembly. THE...

1 min read

A company wanted to replace their gas-fired slot furnaces in their forge shop with induction...

1 min read

Objective A company wanted to braze copper buss plates without using torches. They turned to THE...

1 min read

Objective A company needed to heat a steel mold for a resin bond. They contacted THE LAB at Ambrell...

1 min read

Objective A company wanted to braze steel components, those being a collar and an insert. They...

1 min read

Objective A company needed to preheat alloy wire for their continuous extrusion process. They...

1 min read

Objective A manufacturer of transmission assemblies needed to preheat copper assemblies and...

1 min read

Objective A company wanted to assess using induction heating for their aluminum assembly brazing...

2 min read

Induction heating is a process that uses electromagnetic fields to heat electrically conductive...

2 min read

Induction heating, a process that uses electromagnetic induction to heat electrically conductive...

1 min read

Objective A company had been using a flame for brazing copper assemblies to make electrical...

1 min read

Induction heating is a highly efficient and versatile technology with numerous industrial...

1 min read

Catheter tipping is an important technique in medical procedures that involves shaping the distal...

1 min read

Induction heating, a process that uses electromagnetic induction to heat electrically conductive...

1 min read

Objective A client needed to heat copper and nickel parts prior to bending. The target temperature...

1 min read

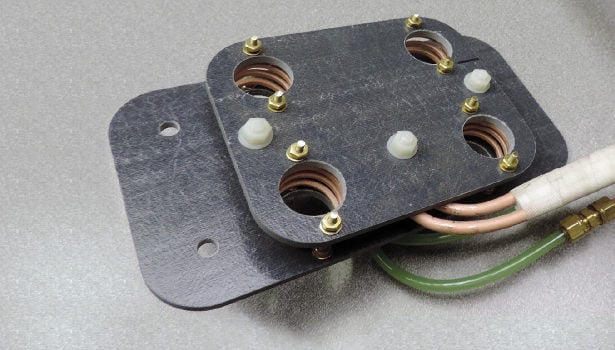

The coil is a critical component of any induction heating solution. Ambrell designs coils for its...

1 min read

Objective A client needed to heat an Inconel tube in order to heat gases. Induction heating can be...

1 min read

Objective A company had been using a torch for a brazing application involving a copper tube and...

1 min read

Ambrell, an inTEST Company and a leading manufacturer of induction heating solutions, will offer...

1 min read

Objective A manufacturer needed to quickly and repeatedly harden steel blades. They turned to THE...

In our latest application video, a single copper wire strand is heated for an enamel burn-off...

1 min read

Companies turn to carbide tipping to enhance the durability and performance of cutting tools....

1 min read

Is your current induction heating system starting to show its age? Are you looking to improve...

1 min read

Objective A battery manufacturer needed to heat battery lugs for a burn-off application. They...

1 min read

Materials science is about understanding the intricate relationship between a material's structure...

1 min read

Objective A supplier of automotive parts needed to heat steel inserts to be placed into a plastic...

1 min read

Objective The intent of this application is to shrink fit (press fit) a steel sleeve. The client is...

1 min read

It's Earth Day, so reviewing the many green benefits of induction heating seems prudent. While...

1 min read

For ammunition manufacturers, consistency is critical. When it comes to shell annealing, the...

1 min read

Induction heating is commonly used in the manufacture of a variety of tools including screwdrivers,...

1 min read

Annealing, a heat treatment process, softens metals by altering their internal structure, making...

1 min read

Objective A manufacturer of bushings for large trucks needed to heat steel tubes for a bonding...

1 min read

Plastisol, a popular coating, relies on precise curing temperatures to achieve optimal results....

1 min read

In the ever-changing world of manufacturing, efficiency, precision, and sustainability are...

1 min read

There is always demand for stronger, safer, and more efficient materials. Induction heating can...

1 min read

A client reached out to THE LAB at Ambrell because they needed to cure oil filters for agricultural...

4 min read

Injection-molded plastic parts are used increasingly in industry, particularly automotive, because...

1 min read

Ambrell, an inTEST company, has just unveiled the EKOHEAT 2, an exciting leap forward for induction...

2 min read

Induction heating has emerged as a preferred technology in the tube and pipe industry, offering...

3 min read

Induction heating has considerable advantages over other common heating methods in specific...

In our latest video, we illustrate why induction heating is a green technology. Induction doesn't...

1 min read

Objective A company that manufactures medical devices needed to heat stainless steel braids for an...

1 min read

Objective A client had been using resistance heating for a copper wire coating removal application...

1 min read

Induction heating is a versatile and efficient method for wire and cable heating applications. It...

1 min read

Induction heating is used for countless industrial heating applications. That said, brazing is...

2 min read

Why choose induction over an oven for manufacturing?

2 min read

Induction heating is used for a number of manufacturing applications in the aerospace and defense...

2 min read

Induction is a non-contact heating method that uses electromagnetic induction to generate heat in a...

Ambrell President Scott Nolen was recently interviewed in a segment that aired on WROC TV 8. During...

2 min read

Induction heating is an ideal process for high volume applications that demand repeatability. That...

2 min read

Induction heating is commonly used in medical manufacturing for a variety of applications. In this...

1 min read

Ambrell was awarded two orders with a total value of over $3.0 million dollars to provide induction...

1 min read

Objective A client needed to heat steel pipe assemblies for a shrink fitting application. The end...

Clients with Ambrell EASYHEAT and EKOHEAT induction heating systems should be aware that we have a...

Ambrell offers a two-day class at its Rochester, NY headquarters that covers Coil Design and...

1 min read

Objective A manufacturer of specialized integrated systems needed an induction system to heat steel...

1 min read

A client contacted THE LAB at Ambrell because they were interested in bringing a desoldering...

1 min read

A client had been using a flame to heat stainless steel housings for removing glass windows, but...

1 min read

Objective A company that manufactures garage door springs contacted THE LAB at Ambrell because they...

1 min read

An aerospace client approached THE LAB at Ambrell with a brazing application. They tried using an...

1 min read

Aluminum is a real challenge to join without specialized brazing equipment. You will need advice on...

1 min read

Objective A company in the business of annealing copper wire connectors contacted THE LAB at...

1 min read

A manufacturer of sink products had been using a torch for brazing brass assemblies. However,...

1 min read

Objective A client contacted THE LAB at Ambrell because they needed to heat brass contacts to...

1 min read

A client came to THE LAB at Ambrell looking to design a process to heat steel shafts for forming to...

1 min read

Objective A client in the power components industry contacted THE LAB at Ambrell because they...

3 min read

About an Induction Forge Induction forging is a process in which an induction heating system...

1 min read

A client needed to heat 0.06" (1.5 mm) stainless steel tubing to 1950 oF (1066 oC) prior to swaging...

1 min read

Objective An engineering firm had a new process that required the removal of a coating of...

2 min read

Induction heating uniformity issues can cause a variety of problems with part quality. We often see...

1 min read

We have collected ten popular Application Notes to help you understand the many ways induction...

1 min read

A client needed to heat steel parts on the inside diameter in order to shrink fit them into each...

1 min read

A client reached out to THE LAB at Ambrell because they needed to heat an aluminum motor housing to...

1 min read

A client from the automotive industry wanted to assess moving from torches to induction for a...

1 min read

Objective A client in the food industry needed to heat the end of a stainless-steel handle with a...

1 min read

A client contacted THE LAB at Ambrell looking to heat copper wire to 500 °F (260 °C) for a wire...

1 min read

A client in the energy storage technology market turned to Ambrell because they needed to heat...

A metals manufacturer recently purchased an Ambrell EKOHEAT® 50 kW induction heating system for a...

1 min read

Objective A client from the medical industry came to THE LAB at Ambrell looking to braze carbide to...

1 min read

A client contacted THE LAB at Ambrell because they were implementing a new brazing process. They...

1 min read

A client manufacturing plumbing flanges came to THE LAB at Ambrell with a brazing application. They...

1 min read

A customer contacted THE LAB at Ambrell because they were soldering brass and copper components...

1 min read

A manufacturer of plastic filtration devices came to THE LAB at Ambrell to see if induction might...

1 min read

Heat staking, also known as metal-to-plastic insertion or indirect induction heating, involves...

1 min read

If you're wondering, "why should I use induction soldering?" then you've come to the right place....

1 min read

In this blog post we'll provide a quick overview of the basics of induction heating. When current...

1 min read

Induction heating has many uses and applications, one of which involves the process of induction...

1 min read

In the last post, we answered some questions regarding how induction hardening work. However,...

3 min read

Coupling is the transfer of energy that occurs in the space between the heating portion of the coil...

1 min read

Hermetic sealing is the process of creating a container of some sort that is airtight. That means...

2 min read

Induction coil design can have a major impact on part quality, process efficiency, and...

1 min read

Our newly updated design guide, titled the Heat Staking Design Guide: Inserting Metal into Plastic...

2 min read

Induction coil design has a major impact on process efficiency and final part quality, and the best...

1 min read

Objective A company had been using a torch for the brazing of automotive parts, but they contacted...

1 min read

Objective A client had a new process and contacted THE LAB at Ambrell to see if induction heating...

1 min read

Objective A client contacted THE LAB at Ambrell because they wanted to replace their torch...

After a busy week at FABTECH Mexico, we were delighted to open THE LAB in Monterrey Mexico....

1 min read

Ambrell, a leading manufacturer of induction heating systems, has sold an EKOHEAT 75 kW/5-15 kHz...

Ambrell and EPGA Induction have opened an Applications Laboratory, sales, and service facility in...

1 min read

A customer had been using an offline oven, but instead wanted the heating to occur within a cell...

1 min read

A customer contacted THE LAB at Ambrell because they had a new application that involved brazing a...

We're pleased to announce that H.Rohloff (Pty) Limited has signed an agreement to become an Ambrell...

1 min read

THE LAB at Ambrell has long offered induction heating feasibility testing, including a half-day of...

1 min read

Objective A client contacted THE LAB at Ambrell because they needed to heat a steel, rubber-coated...

1 min read

A client needed to heat a steel susceptor in order to heat glass rods for a glass cutting...

1 min read

THE LAB at Ambrell tested an induction heating application involving heating a copper assembly for...

1 min read

A company contacted THE LAB at Ambrell because they needed to heat three steel parts for a bending...

1 min read

A client contacted THE LAB at Ambrell because they needed to braze copper tubes for a solar...

2 min read

inTEST Corporation, a global supplier of innovative test and process solutions for use in...

1 min read

inTEST Corporation (NYSE American: INTT), a global supplier of innovative test and process...

1 min read

A client contacted THE LAB at Ambrell because they needed to heat silver bars to 1200 ºF (649 ºC)...

1 min read

A client came to THE LAB at Ambrell needing to heat a 0.85” (21.6 mm) outside diameter magnetic...

Check out the newest induction heating application video from THE LAB at Ambrell. It involves...

1 min read

Objective A client came to THE LAB at Ambrell with an application that involved removing urethane...

1 min read

A client from the automotive industry contacted THE LAB at Ambrell as they needed to solder a pair...

1 min read

Objective A client contacted THE LAB at Ambrell as they needed to anneal aluminum fuel tank fill...

1 min read

A client contacted THE LAB at Ambrell because they needed to heat a block of Haynes nickel alloy...

Wichita State University’s (WSU) National Institute for Aviation Research (NIAR) announced the...

1 min read

A client contacted THE LAB at Ambrell because they needed to heat a steel tube and an aluminum...

1 min read

Objective A company contacted THE LAB at Ambrell to anneal the ends of metal stamp sets of various...

1 min read

A client contacted THE LAB at Ambrell because they needed to heat surgical tools to burn off the...

1 min read

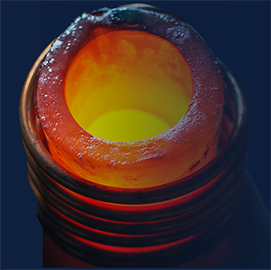

Objective THE LAB at Ambrell tested an induction cap sealing application involving heating aluminum...

3 min read

inTEST Corporation (NYSE American: INTT), a global supplier of innovative test and process...

Manufacturers are creating smart factories across the globe with impressive throughput and enhanced...

1 min read

A client came to THE LAB at Ambrell needing to heat two pairs of fishhooks inside a steel tube for...

1 min read

A client in the high voltage contracting business wanted to move away from flame heating, so they...

1 min read

Objective A client contacted THE LAB at Ambrell needing to heat aluminum molding to activate an...

1 min read

Objective A client needed to heat the stainless-steel substrate of a solar panel shingle in order...

1 min read

A client contacted THE LAB at Ambrell needing to heat a steel band to 1000 ºF (538 ºC) and insert a...

1 min read

A client contacted THE LAB at Ambrell because they needed to temper a spring by heating it to 300...

1 min read

A client contacted THE LAB at Ambrell needing to heat aluminum impeller blades to 200 ºF (93 ºC)...

1 min read

Ambrell Corporation, an inTEST Company and a leading manufacturer of induction heating solutions...

1 min read

A client contacted THE LAB at Ambrell needing to heat steel tubes to 500-1000 ºF (260-538 ºC) for a...

1 min read

A client contacted THE LAB at Ambrell needing to heat a roller assembly to shrink fit it to a motor...

1 min read

THE LAB at Ambrell tested an application that involved heat sealing both ends of a stainless-steel...

1 min read

A client needed to heat magnetic steel pins (spokes) for forging on a rim without heat treating and...

1 min read

THE LAB at Ambrell tested an application that involved heating a graphite crucible to 1,292 ºF (700...

1 min read

A client contacted THE LAB at Ambrell needing to melt ingots of Ticonium and Nobelium in a...

1 min read

A client contacted THE LAB at Ambrell needing to repeatably superheat molten metal with induction...

1 min read

A client contacted THE LAB at Ambrell looking to use induction to prepare cast iron assemblies for...

1 min read

Objective A client contacted THE LAB at Ambrell to heat magnetic steel strips to 1,400 °F (760 ºC)...

1 min read

A client came to THE LAB at Ambrell because they wanted to consider induction heating instead of a...

1 min read

THE LAB at Ambrell tested an induction cap sealing application for a company that manufactures...

1 min read

Objective A company contacted THE LAB at Ambrell to anneal bolt shafts with induction heating. They...

1 min read

A company in the turbine industry needed to heat titanium rod blanks prior to forging them into...

1 min read

A client came to THE LAB at Ambrell needing to braze a joint between a copper lug and nickel-plated...

1 min read

Objective A company contacted THE LAB at Ambrell to heat customer-supplied rods of various...

1 min read

THE LAB at Ambrell tested an induction heating application involving soldering a brass end cap onto...

Ambrell now offers an equipment rental program for its induction heating solutions. With the option...

1 min read

THE LAB at Ambrell tested an induction heating application involving soldering fabric to a Kovar...

1 min read

Objective A client came to THE LAB at Ambrell with an application that involved separating bonded...

1 min read

A client contacted THE LAB at Ambrell looking to assemble connecting rods. Their company was...

1 min read

Objective A client came to THE LAB at Ambrell needing to bond a stainless-steel sheet to a...

1 min read

A client contacted THE LAB at Ambrell because they needed to heat magnetic steel cutting tools with...

1 min read

A new brochure that highlights induction soldering applications is now available. This brochure,...

1 min read

Our new white paper on "Using Induction Heating with Electric Motor and Electric Vehicle...

1 min read

THE LAB at Ambrell tested an induction cap sealing application for a client that manufactures...

1 min read

We're pleased to announce that a new brochure which highlights induction shrink fitting is now...

1 min read

We're pleased to announce that a new brazing white paper is now available. It is titled "Essential...

1 min read

A customer needed to preheat a billet to 250 ºF (121 ºC) for forging. After forging, it was going...

1 min read

A client came to THE LAB at Ambrell with a heat staking application involving heating a knurled...

1 min read

Objective A manufacturer in the medical industry came to THE LAB at Ambrell with a heat staking...

1 min read

A pallet manufacturer needed to heat magnetic steel to 300 ºF (149 ºC) for insertion into a...

1 min read

Objective A medical device manufacturer came to THE LAB at Ambrell needing to heat steel cannulas...

1 min read

Ambrell Corporation, an inTEST Company and a leading manufacturer of induction heating solutions...

1 min read

Objective A customer from the dental industry needed to heat a magnetic steel post to 300 °F (149...

1 min read

Induction heating works because there is an alternating electrical current which is applied to the...

1 min read

A company from the medical device manufacturing industry turned to THE LAB at Ambrell to heat an...

1 min read

Objective A customer needed to heat a stainless-steel needle within a plastic shank to form a...

1 min read

A client came to THE LAB at Ambrell looking to heat two lens housings to 400 ºF (204 ºC) for a...

1 min read

THE LAB at Ambrell tested an induction heating application involving heating a solder joint to...

2 min read

inTEST Corporation (NYSE American: INTT), a global supplier of precision-engineered solutions for...

1 min read

THE LAB at Ambrell tested a cap sealing application for a client. It involved sealing a 1.5” (38.1...

1 min read

A client contacted THE LAB at Ambrell because they needed to shrink fit a carbide ring into a valve...

1 min read

An company came to THE LAB at Ambrell needing to insert brass threaded inserts into seven locations...

1 min read

A client came to THE LAB at Ambrell looking to braze carbide cutting tips to drill bits ranging in...

Learn about what makes Ambrell different in this two-minute corporate overview video. You'll get a...

1 min read

A valve manufacturer that was using a torch to braze several different copper and brass assemblies...

1 min read

A client came to THE LAB at Ambrell looking to braze steel fittings and tubes within a targeted...

1 min read

A client came to THE LAB at Ambrell looking to braze both ends of a steel assembly concurrently....

1 min read

Our Applications Laboratory – recognized in the industry as THE LAB at Ambrell – is known for...

We are pleased to announce that the brand-new EASYHEAT Air is now available. The EASYHEAT Air is a...

1 min read

Objective A research firm needed to heat aluminum and carbon fiber coupons to 392 °F (200 °C) for a...

1 min read

A client from the aerospace industry came to THE LAB looking to heat graphite discs of variable...

1 min read

Objective A client from the automotive industry came to THE LAB at Ambrell with a bonding...

1 min read

The basic principles of induction heating have been used in manufacturing since the 1920s....

1 min read

A company that manufactures, sharpens, repairs and modifies tooling turned to THE LAB at Ambrell....

1 min read

In the latest application video from THE LAB at Ambrell, a cap sealing application is tested. Cap...

1 min read

A battery manufacturer approached THE LAB at Ambrell with a pipe heating application. They had been...

1 min read

A manufacturer of pistons approached THE LAB at Ambrell with a shrink fitting application. They had...

1 min read

Medical device manufacturers commonly turn to induction heating for their manufacturing processes....

1 min read

A client in the aerospace industry needed to braze brass and copper nozzles. They had been using a...

1 min read

A client in the oil and gas industry came to Ambrell with a shrink fitting application. They had...

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service